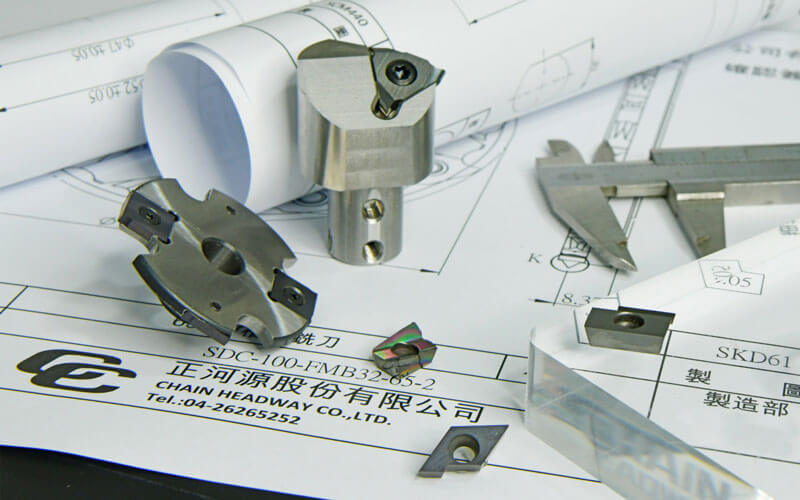

Discover the latest CNC cutting edge solutions from Chain Headway CNC cutting tools with indexable inserts suitable for all materials at EMO Hannover 2023 Hall 04 G89

Come and discover our cutting edge solutions using indexable inserts at EMO Hannover 2023 (Hall 04 G89). Chain Headway has been designing and manufacturing CNC cutting tools and accessories for CNC machining since 1992. We have built our advanced R&D and manufacturing capabilities to offer our customers efficient materials processing solutions across multiple industries.

Industrial materials processing is constantly evolving, and bringing new challenges with the need to cut and mill high temperature alloys and new composite materials. As part of our ongoing commitment to meet technological challenges, we are proud of our excellent record in rapidly developing solutions to meet the emerging material processing needs of our customers.

Three ways Chain Headway maintains leadership in cutting tool technology

- Partnership with the University of Science & Technology (Taiwan) for professional development of cutting technicians

- Efficient, integrated production facilities that combine management, research and development and automated production processes

- The latest European and Japanese production and inspection technologies ensure the highest standards of quality control and efficient manufacturing

CNC Cutting Tools With Indexable Inserts At EMO Hannover 2023

We will be showcasing our indexable insert technology for CNC cutting tools from 18-23 September at EMO Hannover 2023, Hall 04, Booth G89. Our team of R&D professionals bring decades of experience in technical solutions and cutting tool development to offer our customers the best CNC cutting tool technology with options for all types of materials.

Extraordinary CNC Cutting Tool Technology Comes From Structured Innovation

Our structured innovation pathway to cutting tool solutions delivers the highest utility and performance at the best possible price. We apply advanced techniques in a customer focused process that enables us to deliver designs to your specific needs. Our expertise includes deep and large area cutting tools, negative rake inserts, adjustable angle chamfering cutters, and more. We are deeply committed to providing you with efficient, innovative, customized solutions

The six development stages of new cutting tool design & manufacturing

- Carrying out analysis of the customer requirement

- Identifying the correct technological approach for the design

- Developing the cutting tool solution

- Designing the clamping system solution

- Manufacturing the new CNC cutting tool

- Testing to meet approval criteria and carrying out performance analysis

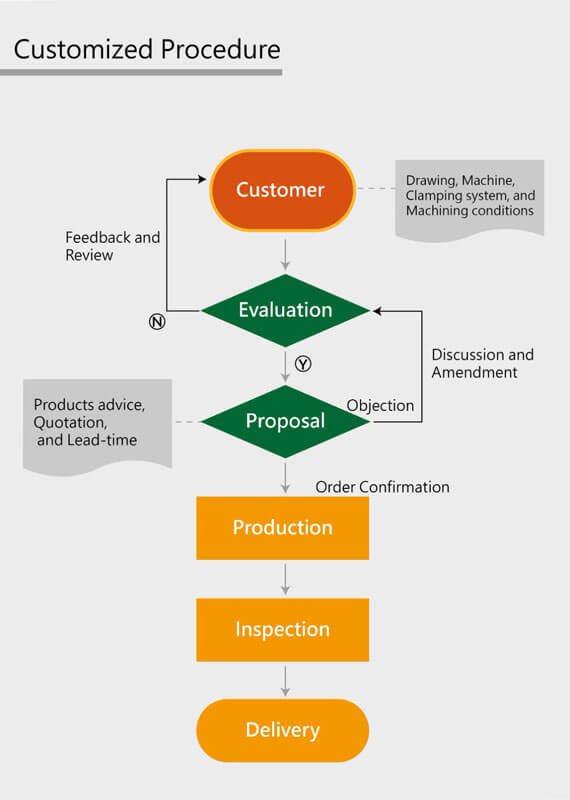

Customized CNC Cutting Tool Development & Manufacturing

At Chain Headway we offer you a staged, structured, method for ensuring you get the exact CNC cutting tool solution that you need for your specific project requirements. The following flow chart indicates the optimized pathway we follow to achieve your CNC cutting tool goals.

Customer Case Studies

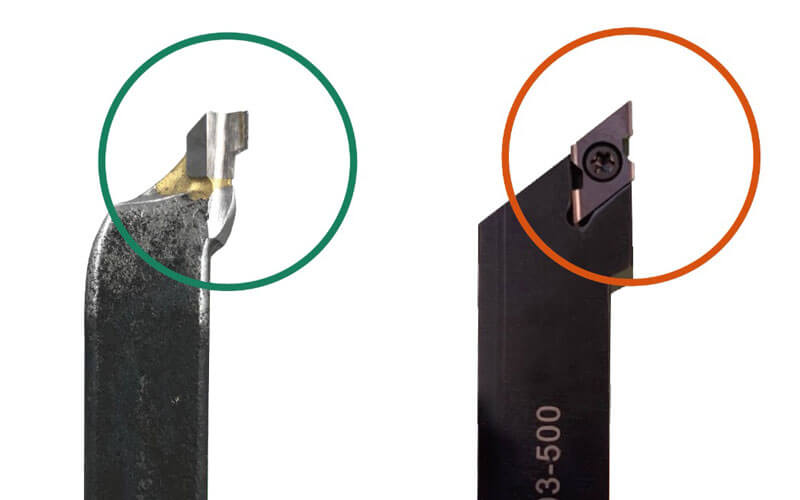

We work with our customers to design the best insert option for their cutting and material requirements. Our case studies demonstrate how disposable indexable cutting tools can be used as direct substitutes for traditional welded blades.

What are four significant benefits of changing to Chain Headway indexable inserts?

- quickly replace blades

- reduce tool calibration time

- reduce storage space

- achieve production automation

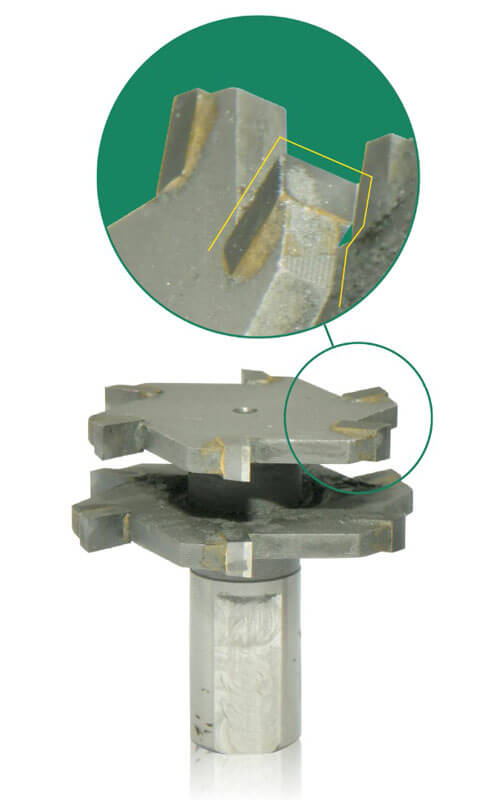

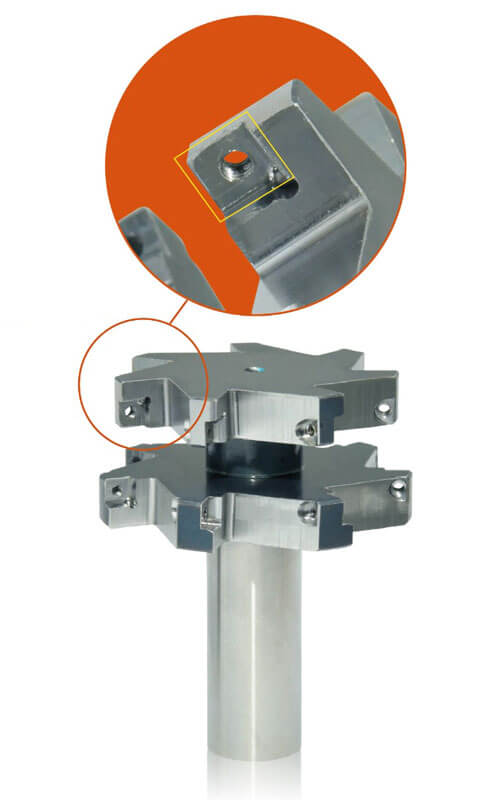

Why Should You Change From Carbide Welded Milling Cutters To Indexable Milling Cutters?

Carbide welded cutters like the one shown above need to be replaced or reground whenever the cutting edge is worn. Our customers find this is both inefficient and expensive. When blades are reground cutter compensation needs to be calculated to maintain accuracy. This is a time-consuming process that adds to the costs of using welded cutters, and when the cutter is severely worn it is necessary to purchase a new one.

Indexable milling cutters are much more efficient than welded milling cutters as well as offering consistent precision and performance. When the edge is no longer sharp it is only necessary to change the insert, no need for grinding or purchasing a new cutter.

In this case study, our customer presetting time was reduced from 30 minutes to 5 minutes, with no requirement for cutter compensation calculations and adjustments. The customer also experienced a significant gain in workpiece machining volume from 30,000 to 120,000 pieces by changing to our indexed insert cutters.

Changing From A Carbide Welded Single Blade Cutter To An Indexed Cutter To Maximize Production Efficiency

In the example above, you can see the difference between a carbide welded cutter and the indexable milling cutter that we designed to replace it. Our customer discovered that production efficiency in tool presetting was optimized by a factor of six times when using the indexable milling cutter. Machine downtime is reduced from 30 minutes to 5 minutes, keeping production running smoothly.

Our Four Principles for Successful Cutting Tool Manufacturing

1. We are Innovative

As a vertically and horizontally integrated cutting tool manufacturing company, our approach to innovation cuts across management, organizational, information, technological and service functions to maximize sustainable benefits for our customers

2. We are Fast

We know that time is an expensive commodity for our customers. Our responsive, rapid service comes from our long experience in building operational efficiency, and is a significant success factor in our highly competitive market segment.

3. We are Reliable

We believe in developing long term relationships with our customers, fostering friendly and supportive interactions between staff, customers, suppliers and partners. Our reliable, honest, service supports all of our stakeholders, clients and partners as we continue to grow and consolidate our business.

4. We are Responsible

We recognize that the success of our business depends on what we can offer to society as well as maintaining the highest standards of business ethics and product quality. We apply green energy, energy saving, carbon reduction and environmental protection methodologies to minimize environmental impact and build positive social values

How is Cutting Tool Technology Affected by Manufacturing Trends?

There is a historic trend towards very precise, fine, and accurate machining that has driven development of the current generation of cutting tool technologies. For example, today in 2023, indexable CNC cutting tools with replaceable blades are becoming more popular than traditional carbide tipped CNC cutting tools.

The Chain Headway cutting system enables you to decide on the most efficient cutting edge type and insert coating for CNC cutting of any specific material you need to machine. The growing trend towards total automation of manufacturing and reduction in highly trained labor makes simpler insert-based CNC cutting tools a much more efficient option than traditional tools.

What are the three critical factors in cutting tool design?

- Time – increased durability to extend tool life, simpler, faster, tool setting

- Efficiency – increasing production efficiency and reducing presetting overheads

- Stability – predictable and consistent tool performance improves accuracy and safety

Achieving Precision Through Quality Control

We deliver very consistent and dependable high quality products to our customers and partners to meet all their cutting needs for various material options. This is achieved by rigorous inspection processes utilizing state of the art tool inspection technology.

Chain Headway CNC Cutting Tool Solutions

Chain Headway indexable insert technology is one of the many solutions we have pioneered to meet your CNC machining needs, and is compatible with a very wide range of cutting requirements and materials. Our cutting tool technology is being used by industries from medical component manufacturing to aerospace engineering. Please check our online catalog for more information about our range.

Please contact us to discuss how we can supply you with both standard and customized CNC cutting tool solutions and accessories that will improve your cutting, milling and chamfering efficiency and precision.