As a leading global manufacturer of cutting solution, Chain Headway will be exhibiting our CNC diamond brushes series at EXPOMAQ 2024 in Poliforum León, Guanajuato, Mexico from June 18 to June 20, 2024. We look forward to seeing you there, and will also be online to answer product inquiries and questions during the show.

One of the major challenges in metalworking is the complexity of operations that are difficult to replace with machinery. These processes often require expensive customized equipment. General mechanical equipment is often limited by product versatility and struggles to meet the specific needs of various metalworking tasks. In the machining process, surface treatment is a crucial step that not only affects the appearance of the workpiece but also directly influences its functionality and performance. Chain Headway’s DMB Diamond Grinding Brush brings new possibilities to metalworking.

By integrating diamond grinding brushes into mechanical equipment, it successfully reduces reliance on manual labor while addressing issues of labor shortage and instability.

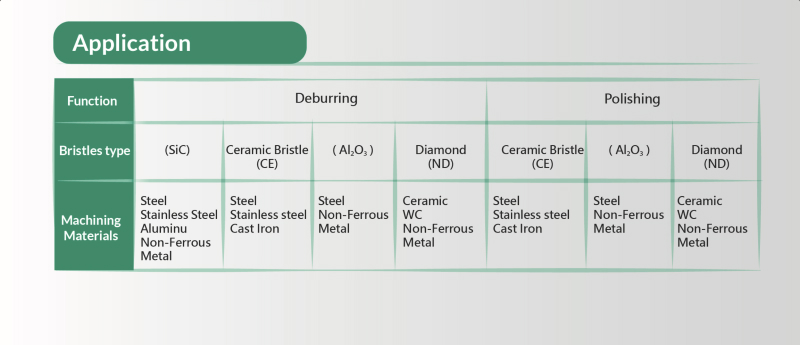

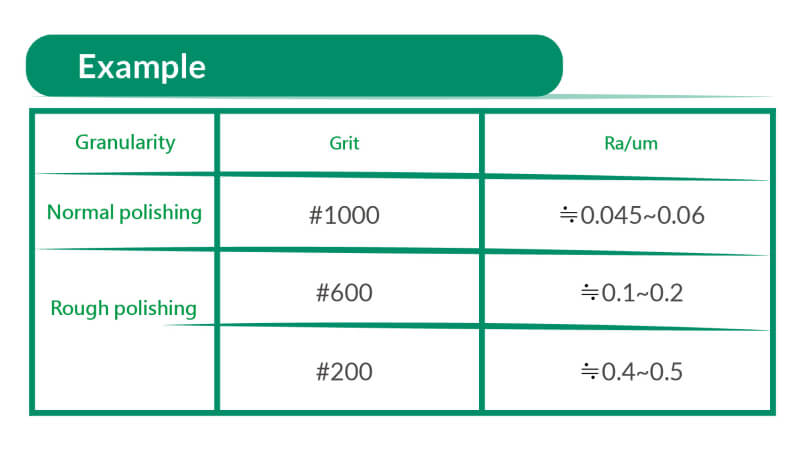

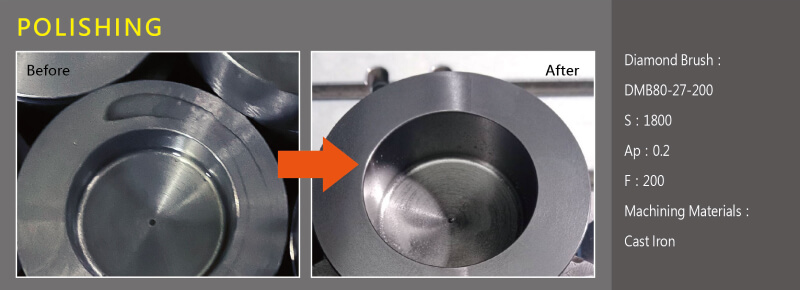

The DMB Diamond Grinding Brush can be applied to a variety of workpiece materials, including aluminum, steel, nickel-based alloys, and tungsten carbide, as well as other hard and brittle materials. Using different grit sizes (#200, #600, and #1000) of diamond grinding brushes, it can address tool dulling, glass ceramics, quartz, nickel-based alloys, and all heat treated surfaces. It effectively removes cutting marks, deburrs, polishes surfaces, and removes rust, resulting in a smooth and polished workpiece surface.

Key Features of DMB Diamond Brushes

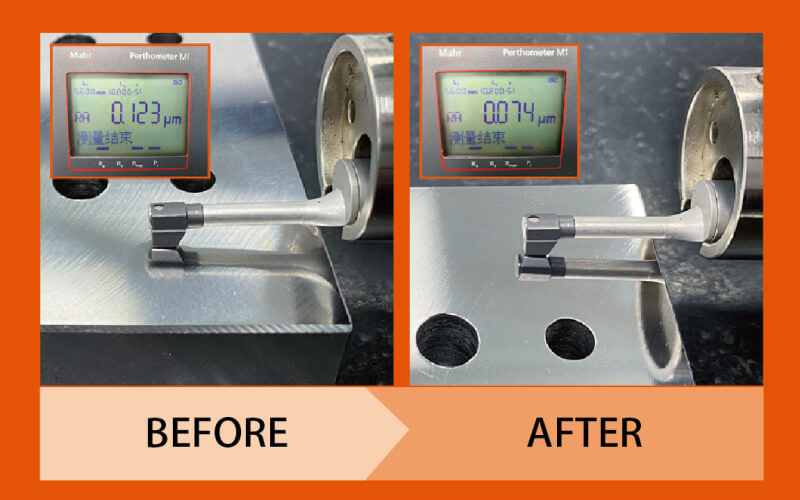

- Efficient Deburring and Polishing: Can remove burrs and achieve a polishing effect, with high strength, excellent resilience, and fatigue resistance.

- High Hardness Processing: Capable of processing materials with a maximum hardness of up to HRC60°.

- High Heat Resistance: Withstands temperatures up to 180°C.

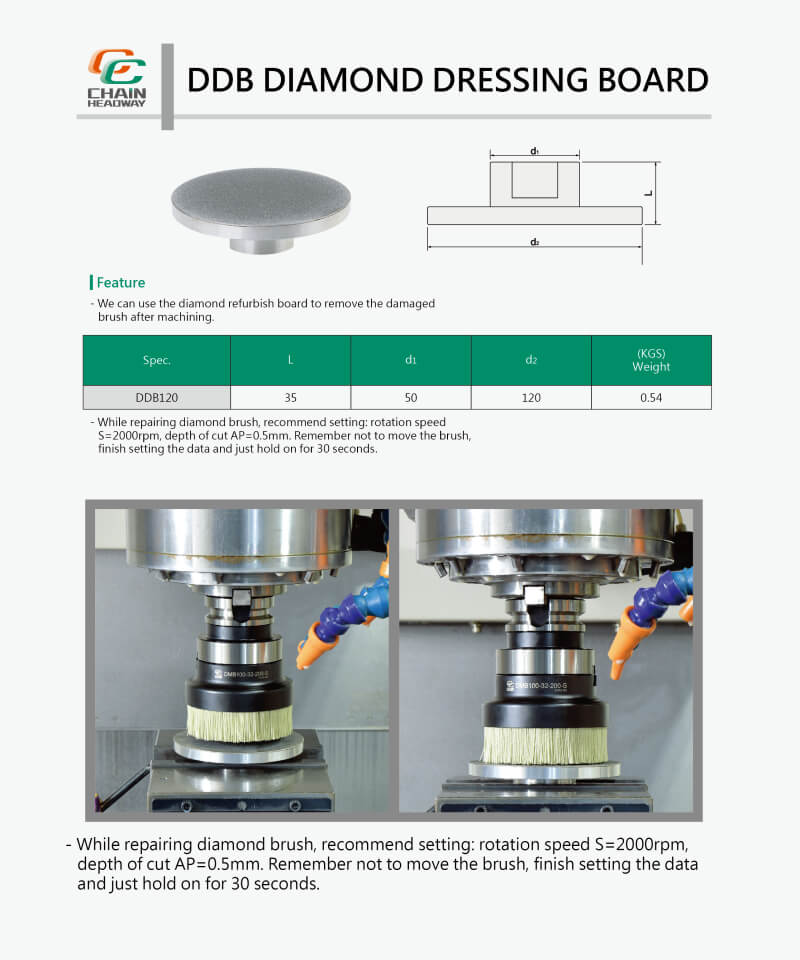

- Extended Lifespan and Maintenance: The DDB Diamond Dressing Board can restore the brush’s flatness, extending its service life and saving time and labor costs.

- Time and Effort Saving: Improves surface roughness efficiently.

DMB Diamond Brushes are available in three types and sizes for various applications

To address diverse processing conditions and different sizes, shapes, and materials of workpieces, users can select the appropriate diamond grinding brush. This is particularly useful for flat or irregularly shaped workpieces, allowing for easy adaptation to different processing needs. Therefore, the Chain Headway Diamond Brush series has developed three sizes:

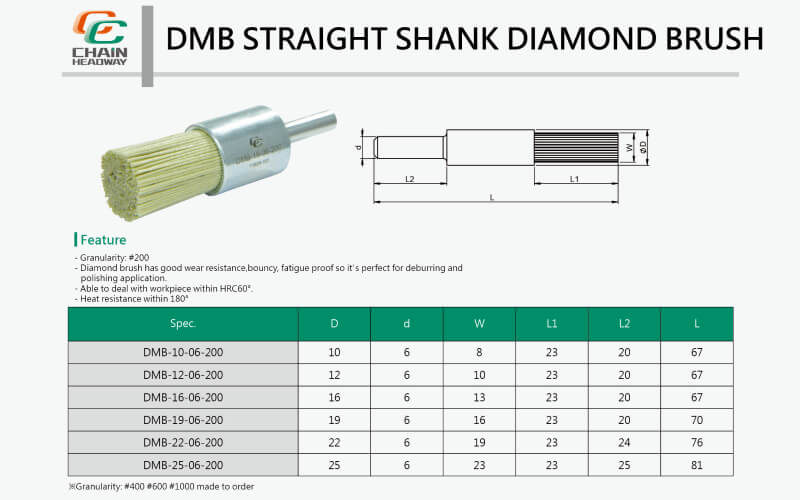

- Straight Shank Diamond Brushes, ⌀10-25mm

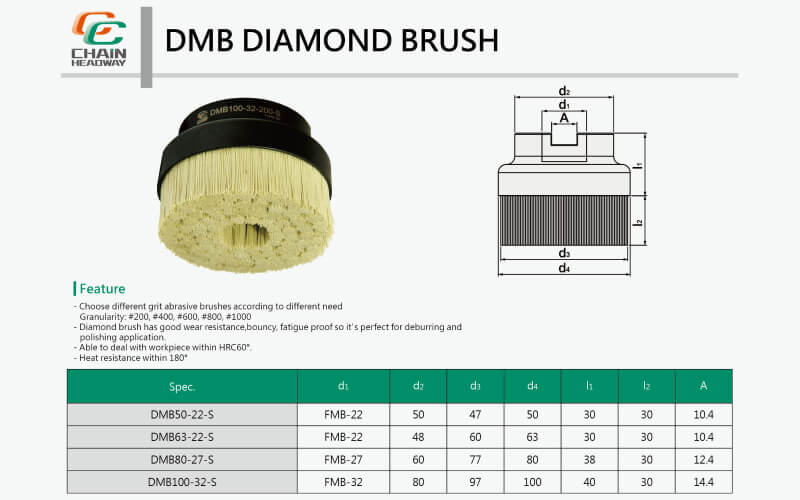

- Shell Type Diamond Brushes, ⌀50-100mm

- Straight Shank T-type Diamond Brushes, ⌀25.4-63.5mm

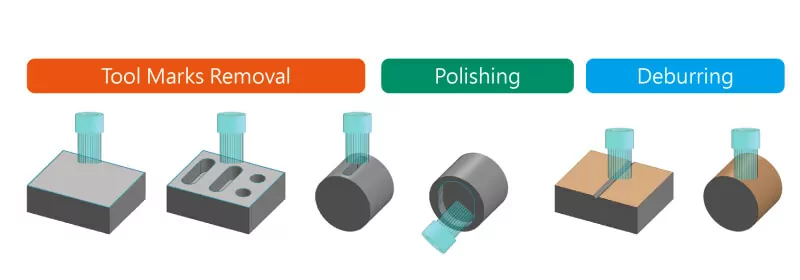

Usage of DMB Diamond Brushes

- The grinding path should be completely larger than the workpiece, so the selected grinding brush diameter should be larger than the workpiece diameter.

- It is recommended to set the cutting depth(Ap) of the diamond brush to 0.5~2mm and the speed(S) to 1000~4000 rpm. It should be used with cutting fluid for cooling.

- The cutting diameter of the diamond brush should be between 25%~45% for optimal deburring results.

- For removing burrs on edges, such as when milling with cutting tools, the spindle should rotate clockwise, and it’s recommended to use the diamond brush in reverse rotation of the spindle.

Real Machining Case

- Case One: Removing Machining Marks

- Case Two: Deburring

- Case Three: Surface Polishing

The exceptional performance of the DMB Diamond Brush allows for stable and precise machining of metal workpiece surfaces, saving both labor costs and significantly enhancing production efficiency. Additionally, it can meet diverse machining requirements, effectively improving workpiece surface roughness and bringing higher benefits to the production process.

Upcoming 2024 Exhibition Info

- Exhibition: Mexico EXPOMAQ 2024

- Date: June 18 ~ June 20, 2024

- Location: Poliforum León, Guanajuato

- Booth No.: C4, 1826

- Exhibition: India AMTEX 2024

- Date: July 26 ~ July 29, 2024

- Location: Pargati Maidan, New Delhi

- Booth No.: Hall 7ABC, H7A24

- Exhibition: Chicago IMTS 2024

- Date: September 09 ~ September 14, 2024

- Location: McCormick Place, Chicago, IL

- Booth No.: W3, 431855

- Exhibition: Japan JIMTOF 2024

- Date: November 05 ~ November 10, 2024

- Location: Tokyo Big Sight, Tokyo

- Booth No.: TBA

For more information and the latest updates, visit our official website or follow us on Instagram, Facebook, and LINE. To explore our full product range, please download the catalog here: Deburring Removing Machining Marks Polishing.

Let’s work together to unlock cutting-edge and efficient machining solutions!