Our cutting tool series delivers outstanding milling and chamfering performance with indexable inserts for aluminum and alloy steel

Chain Headway manufactures a series of deep and large area CNC cutting tools. These use our long edged milling inserts in micro grain cemented carbide for precision machining, surface finishing, cutting and chamfering up to a depth of 30mm.

Chain Headway long edged milling inserts for CNC cutting

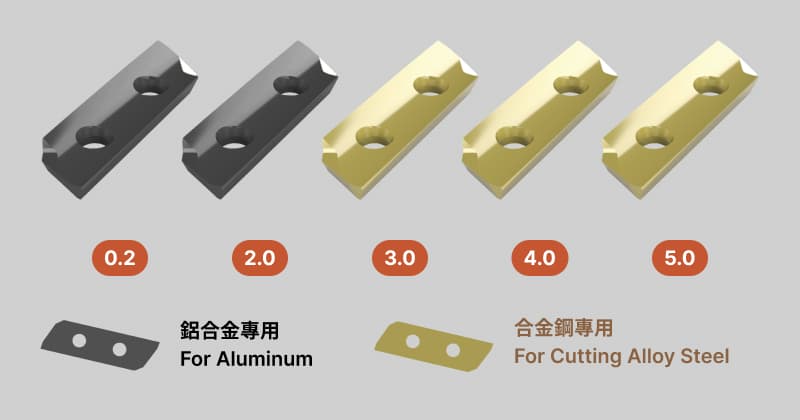

The combination of our innovative AE32 series long edge milling inserts with our indexable, shell, and chamfering cutters enables rapid, precise deep and large area CNC machining. You can easily work with either aluminum or alloy steels by fitting the correct insert for the material type.

We manufacture our AE32 series inserts with five corner radius options from 0.2mm to 5.0mm for maximum flexibility in profile cutting. All inserts have a 32mm cutting edge and can be used for both milling and chamfering when fitted to the appropriate tool.

What are 5 applications of long edged milling cutters?

- cavity milling

- contour milling

- face milling

- groove milling

- step milling

Inserts have significant advantages over standard tools as they can be rapidly replaced with fresh inserts rather than requiring sharpening when cutters become worn, and can be changed to suit different materials and profiles without needing to purchase a new cutting tool.

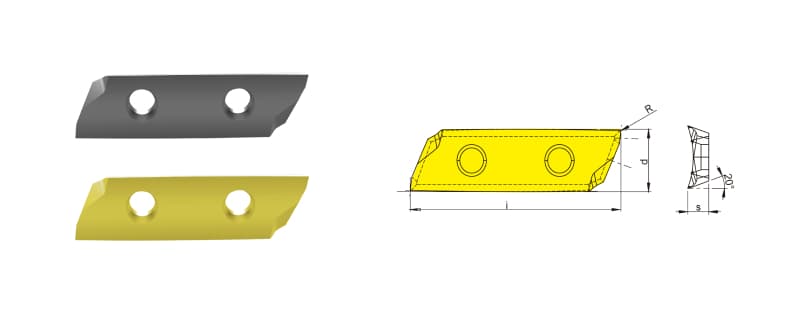

AECX32T3 long edge milling insert

The Chain Headway AE32 series of milling inserts are designed to work seamlessly across our range of deep and large area cutting tools for maximum convenience and efficiency. Our latest range of inserts offer solutions for milling and contouring of aluminum alloys and non-ferrous metals, alloy steels and cast iron up to a maximum cutting depth of 30mm.

Advanced fully ground edge design with five corner radius options improves precision and consistency for deep cutting as well as both rough and precision machining and milling. High rake cutting angle improves surface finish by clearing chips rapidly and insert coatings reduce friction for improved machining efficiency.

Technical specifications of AECX32T3 long edge milling inserts

Manufactured with micro grain cemented carbide, the new Chain Headway AECX32T3 cutting insert enables high precision machining of aluminum, aluminum alloys, alloyed steels, stainless steels and cast iron.

AECX32T3 cutting parameters

| Machining material | Grade | Cutting velocity Vc (m/min) | Feed rate per blade | Cutting Condition |

| Aluminum / Al Alloy | OM5005 | 500-1800 | 0.05-0.25 | Interrupted Cutting |

| Aluminum / Al Alloy | OM5060 | 500-1800 | 0.05-0.25 | General Cutting |

| Alloyed Steels Stainless Steel Cast Iron | OM5035 | General Cutting |

AECX32T3 dimensions

| Insert | d (mm) | l (mm) | s (mm) | R (mm) |

| AECX32T302ER-F01 | 11.9 | 37 | 3.97 | 0.2 |

| AECX32T320ER-F01 | 11.9 | 37 | 3.97 | 2 |

| AECX32T330ER-F01 | 11.9 | 37 | 3.97 | 3 |

| AECX32T340ER-F01 | 11.9 | 37 | 3.97 | 4 |

| AECX32T350ER-F01 | 11.9 | 37 | 3.97 | 5 |

Benefits of Chain Headway indexable inserts

We are pioneers in indexable insert technology, and manufacture a wide range of cutting tools with replaceable inserts. Applications of our technology range from medical component manufacturing to aerospace engineering. Please browse our catalog for details of our entire range.

Cut different materials with the same tool by changing inserts

You can simply change the insert type to switch between cutting alloyed steels or aluminum alloys. This is significantly cheaper than purchasing individual tools for each material.

Sharp inserts create excellent finishes

Because the supplementary insert has a very sharp cutting edge, this reduces secondary burring. Ease of replacement of inserts eliminates the need to sharpen tools, and a fresh insert can be fitted to guarantee excellent finishes with every cut.

Key features of Chain Headway long edge replaceable inserts

| Cutting Depth | Make safe, precise cuts up to a depth of 30mm |

| Versatile Cutting | Suitable for deep cutting, rough cutting and precision machining. |

| Convenient Quality | Eliminate loss of precision through the need to regrind and sharpen welded cutters. Insert blades are easy to replace when showing signs of wear. |

| High precision | Fully ground insert to improve precision and consistency of cutting |

| High rake cutting angle | High rake cutting angle promotes chip evacuation and improves surface finish |

| Five types of corner radius | Available with a corner radius of 0.2, 2.0, 3.0, 4.0 or 5.0mm |

| Cut Different Materials | Cut aluminum alloys, non ferrous metals or alloy steels with the same tool by changing the cutting insert to the specification required. |

| Improved Safety | Precision cutting reduces potentially hazardous burring and chipping |

| Improved machining efficiency | Cutting edge design and coating technology reduces surface friction and increases thermal resistance. |

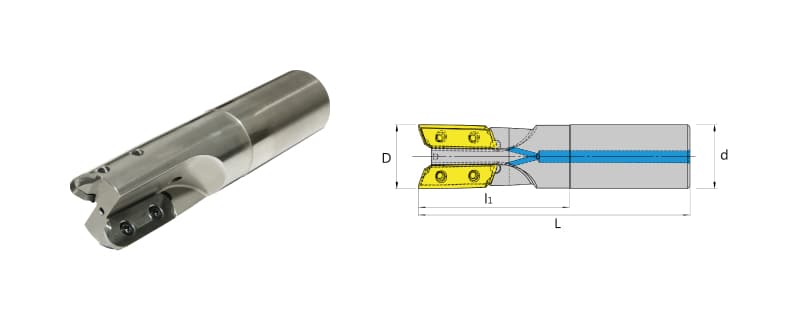

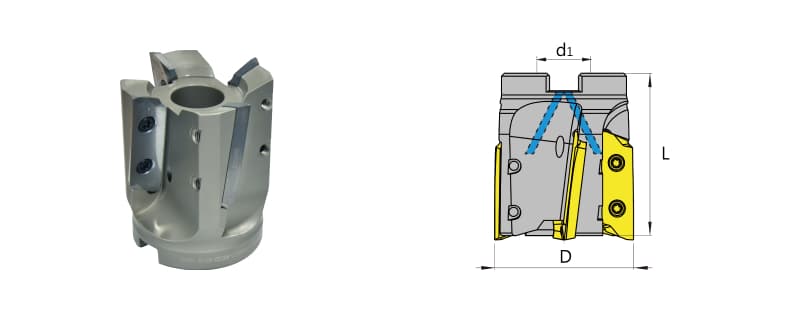

Hurricane indexable milling cutter

The Chain Headway HRCN Hurricane Indexable Milling Cutter is available with effective cutting diameters of 32, 33 and 40mm. The Hurricane milling cutter is designed to be fitted with replaceable AE32 series inserts suitable for precision milling in aluminum alloy or alloy steel.

Technical specifications hurricane indexable milling cutter

| Model | L | h | D | d | Flutes | Insert |

| HRCN-3232-AE32-135L-2T-C | 135 | 75 | 32 | 32 | 2 | AE.32T3 |

| HRCN-3332-AE32-135L-2T-C | 135 | 75 | 33 | 32 | 2 | AE.32T3 |

| HRCN-4032-AE32-135L-2T-C | 135 | 75 | 40 | 32 | 2 | AE.32T3 |

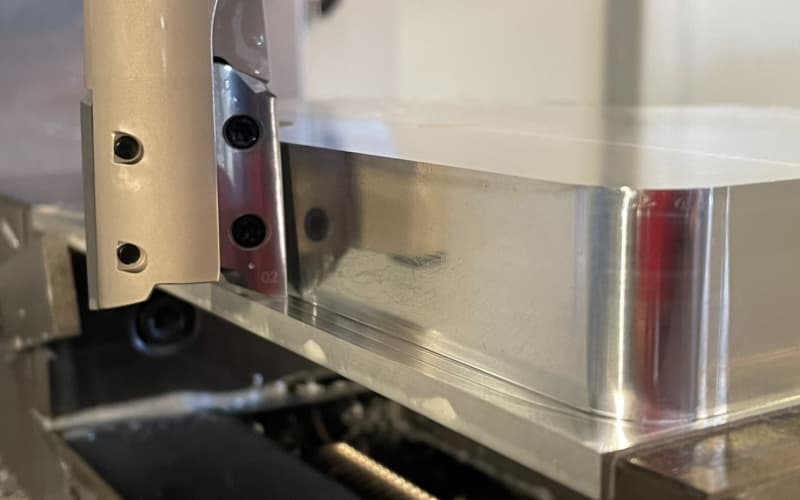

Hurricane shell milling cutter

The Hurricane milling cutter is also available as a shell milling cutter, using the same long edge inserts. The shell configuration allows for effective cutting diameters up to 80mm with the same precision cutting you can expect from Chain Headway AE.32T3 inserts for aluminum alloy and alloy steels.

Example uses of the Hurricane long edged milling cutter

Technical specifications hurricane shell milling cutter

| Model | L | d1 | D | Flutes | Insert |

| HRCN-500-FMB22-AE32-4T-C | 60 | 22 | 50 | 4 | AE.32T3 |

| HRCN-630-FMB22-AE32-4T-C | 60 | 22 | 63 | 4 | AE.32T3 |

| HRCN-800-FMB27-AE32-4T-C | 70 | 27 | 80 | 5 | AE.32T3 |

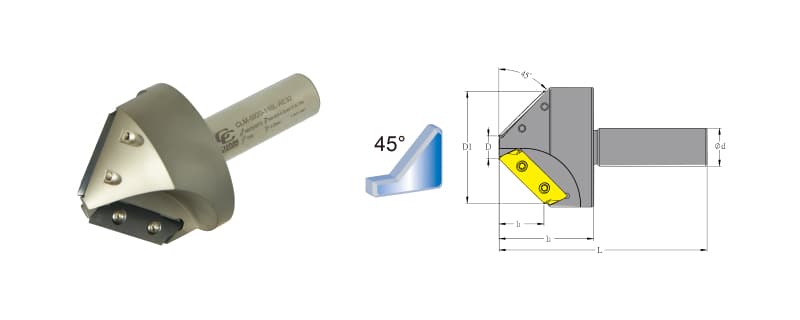

CLM long edge chamfering cutter

The Chain Headway CLM long edge chamfering cutter features a standard 45 degree cutting angle. Replaceable AECX32T3 inserts create excellent chamfered surfaces with very high precision and finish.

| Model | L | D | D1 | d | l1 | l2 | Insert | Weight |

| CLM-5920-110L-AE32 | 110 | 12 | 59 | 20 | 23.7 | 50 | AECX32T3 | 0.7kg |

| CLM-5932-110L-AE32 | 110 | 12 | 59 | 32 | 23.7 | 50 | AECX32T3 | 0.9kg |

Using the AECX32T3 long edge insert extends the chamfering range (fromØ13~58mm).

Example setup of CLM long edge chamfering cutter

Example applications of machine settings for the CLM-5920-110L-AE32 long edge chamfering cutter with a 20mm diameter shank cutting aluminum alloy and alloy steel using the appropriate AE32 series inserts.

Example Setup |  |  |

Material | Aluminum Alloy | Alloy Steel |

V (m/min) | 220 | 160 |

S (rpm) | 1430 | 1040 |

f (mm / rev) | 0.2 | 0.12 |

F (mm / min) | 570 | 250 |

Tool diameter (mm) | 49 | 49 |

No. of blades | 2 | 2 |

Chain Headway deep & large area cutting tools

Please contact us to discover how our deep & large area cutting tools can help you improve cutting, milling and chamfering productivity and performance. Our highly efficient cutting tools offer flexible solutions to all your machining requirements.