Cutting & Milling Tools Designed To Combat Abrasion & High Temperatures

Traditional Steel & Carbide Tools Not Suitable Cutting Tools For Composites Machining

The inclusion of carbon, kevlar, glass and thermally insulating materials and compounds make composite materials highly abrasive and increase tool tip heating, wear and breakage. Traditional steel and carbide tools are cheap per unit, but have a very short life as composite material cutting tools.

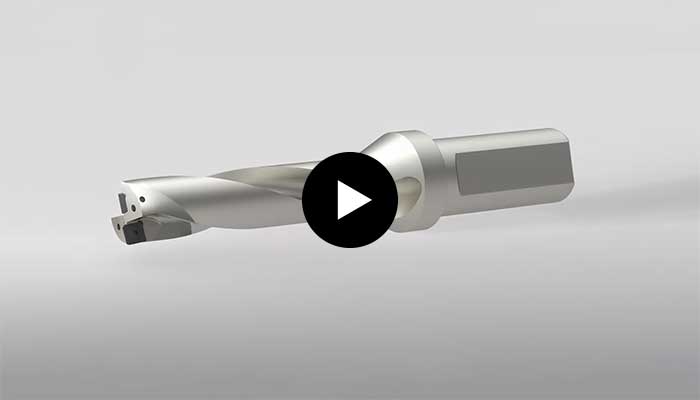

Our PCD (polycrystalline diamond) tipped milling cutters and turning tools survive much longer in this harsh application and are more cost effective in price per part manufactured. Chain Headway designs and manufactures a range of PCD tipped tools specifically for these applications and have also designed a tool coated with PVD for cutting very hard composites.