In high-stress, frequent assembly/disassembly, and high-corrosion-risk environments, traditional alloy steel screws and industrial fasteners often suffer from severe wear, thread stripping, and rust. Chain Headway introduces the SAS Special Alloy Steel Screws—manufactured in Taiwan using premium Japanese-imported alloy materials. These high strength bolts offer ultra-high tensile strength, exceptional wear resistance, and outstanding corrosion protection, making them the ideal upgrade over standard Grade 12.9 screws.

Why Choose SAS Special Alloy Steel Screws?

✅ 33% Strength Boost with SAS Screws

- SAS screws meet ISO 16.9 strength grade, making them reliable ISO grade 16.9 fasteners for demanding applications.

- Approx. 33% higher tensile strength compared to standard Grade 12.9 (ISO 12.9) screws.

- Ideal for high-load clamping, heavy-duty structural fastening, and frequent assembly/disassembly operations requiring high tensile strength bolts.

✅ Proven Wear Resistance

- SAS screws maintained excellent thread integrity even after 30 actual tightening cycles.

- In contrast, traditional alloy steel fasteners showed severe wear and galling damage after just 10 cycles.

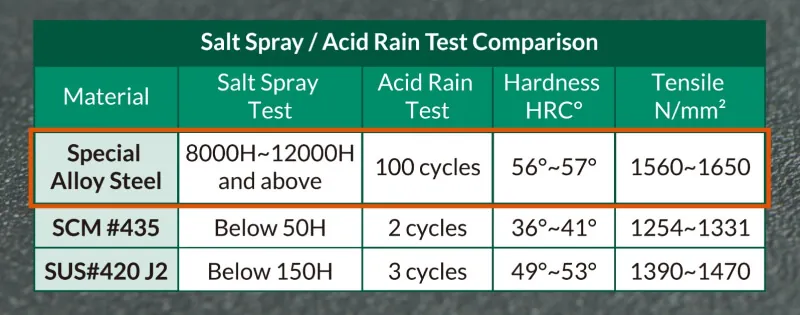

✅ Superior Corrosion Resistance in Extreme Environments

- These anti-corrosion screws resist rust and deterioration, even in harsh industrial and coastal conditions.

✅ Recommended: Use with “TW Torque Wrench”

- Ensures consistent installation torque for every screw

- Enhances assembly precision and structural safety

Recommended Application Scenarios

- Machine tools and jigs assembly where precision fastening is critical

- Heavy industrial equipment (e.g., hydraulic systems, die-casting modules)

- High-frequency assembly/disassembly areas in electronic and automation equipment

- Corrosive environments such as coastal areas and high-humidity, high-temperature regions for fasteners.

Frequently Asked Questions about SAS Screws

- Q1: What is the difference between SAS Special Alloy Steel Screws and Standard Grade 12.9 screws?

A: SAS screws offer approximately 33% higher tensile strength, better wear resistance, and superior corrosion protection than standard Grade 12.9 screws. - Q2: Can SAS screws be used in coastal or high-humidity environments?

A: Yes. SAS screws are specifically designed to resist corrosion in extreme environments, including coastal regions and high-temperature, high-humidity settings.

For more information and the latest updates, visit our official website or follow us on Instagram, Facebook, and LINE. To explore our full product range, please download the catalog here: SAS Special Alloy Steel Screws

- 📞 Contact Us: +886-4-26268383

- 🌐 Website: www.chainheadway.com

- 📧 Email: [email protected]

- 📲 Follow Us for Updates: Instagram / Facebook / LINE – Search for “Chain Headway”