As a leading global manufacturer of chamfering and cutting tools, Chain Headway will be exhibiting our CNC chamfering end mill cutters at EMO Hannover Innovate Manufacturing 2023 in Messegelände D 30521 Hannover from 18 September to 23 September 2023. The bi-annual EMO Hannover 2023 exhibition is the premier international exhibition for the metalworking industry. We look forward to seeing you there, and will also be online to answer product inquiries and questions during the show.

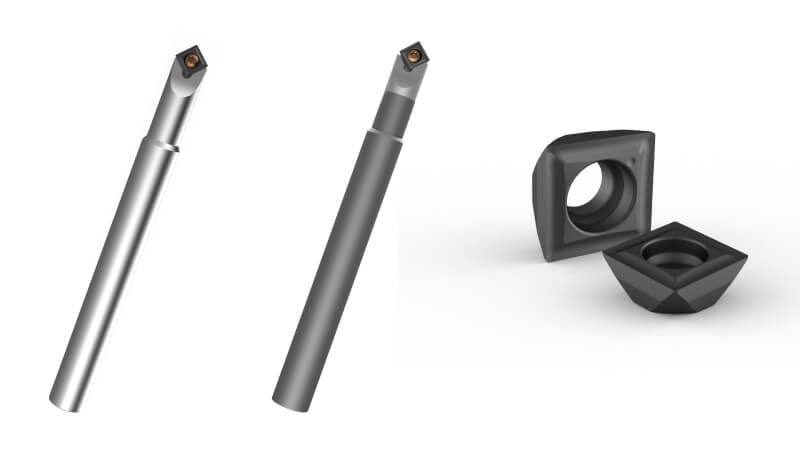

MSP & CMSP Indexable Mini-Chamfering End Mill Cutters

Chain Headway MSP and CMSP series chamfering cutters feature our innovative replaceable SBGT050202-F01 square insert with 4 cutting edges. All four sides can be used by rotating the insert to supply a fresh sharp edge as each side becomes worn. This offers up to four times the life of a conventional cutter. One tool can also cut different materials by changing the type of insert to suit the material being cut.

What are 4 uses of mini-chamfering end mill cutters?

- Chamfering

- Grooving

- Spotting

- Engraving

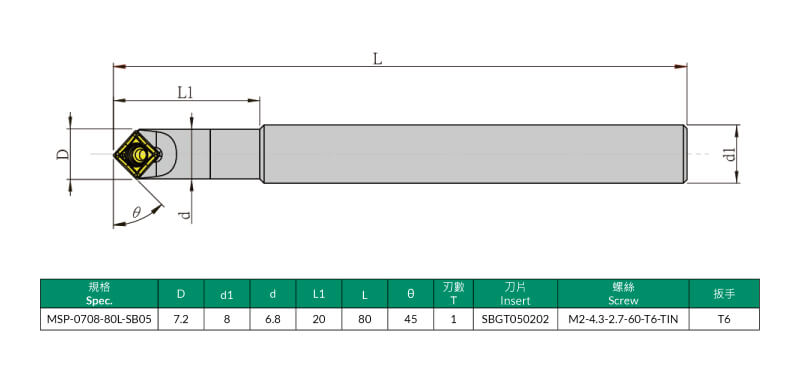

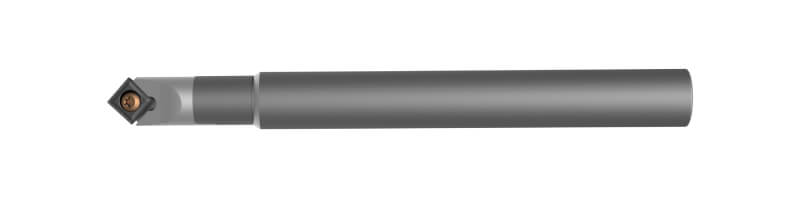

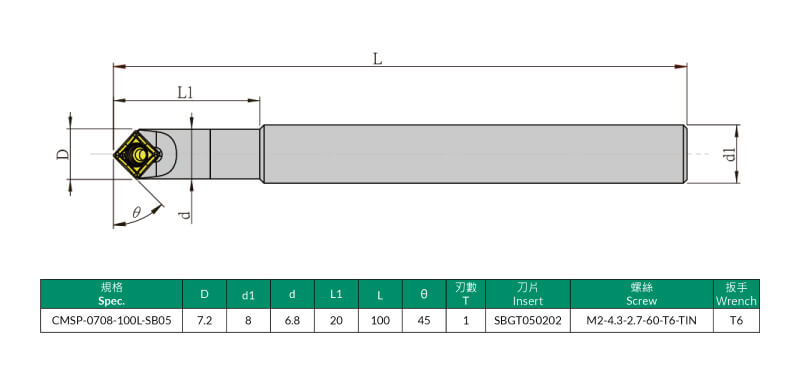

The MSP shank is made of alloy steel as an economical option and where extreme precision and tool durability is not of the highest importance. CMSP has a shank made of tungsten carbide for better rigidity, higher precision and extended tool life.

What are 3 features of Chain Headway Indexable Mini Chamfering End Mill Cutters?

- Slim design for chamfering small diameters

- Chamfering degree: 45°

- Smallest cutting diameter: 5.5mm

Chain Headway MSP and CMSP series chamfering cutters feature our innovative replaceable SBGT050202-F01 square insert with 4 cutting edges. All four sides can be used to supply a fresh sharp edge each time, offering four times the life of a conventional cutter. One tool can also cut different materials, such as steel, aluminum, cast iron or stainless steel simply by changing the insert type.

Applications of Chain Headway Chamfering Cutters

- Inside Chamfering

- Outside Chamfering

- Profile Chamfering

- V-Grooving

- Spotting

- Face Grooving

- Carving And Engraving

Our chamfering cutters are perfect for inside, outside and profile chamfering, groove cutting, and engraving in milling machines, CNC milling machines and CNC lathes. Our MSP and CMSP 45º cutter can also be used for spotting and carving. Because of their small size, both MSP and CSMP are ideal for electronic and watchmaking applications.

What Are The Key Features Of Chain Headway MSP & CMSP Indexable Mini-Chamfering End Mill Cutters?

The unique design of our MSP and CMSP mini-chamfering end mill cutters offers considerable time and cost savings compared to conventional chamfering cutters.

For improved durability and finish, the Carbide CMSP indexable mini-chamfering end mill cutter offers clean, high precision cutting in a cost-effective package.

- Use all four sides of the insert for extended life

- Use the same tool to easily cut different materials

- Excellent finishing

- Improved safety features

Inserts can be used on all four sides

Using all four sides of our innovative square indexable blade removes the need to regrind worn edges. This offers a longer working life than conventional tooling. The secure and reliable indexable insert blade enables high precision chamfering.

Easily cut different materials with the same tool

Simply change blades to cut alloyed steels, stainless steels, cast iron or aluminum. You can achieve significant cost savings compared to purchasing a different tool for each material.

Excellent finishing

The supplementary blade has a very sharp cutting edge, which reduces secondary burrs after chamfering. Improved quality of finish also makes the working environment safer. The Carbide CMSP mini-chamfering end mill offers the highest standard of finish.

Improved Safety

The secondary relief angle of the cutting edge is set to reduce the risk of operational interference with the work piece and maximize clearance. 45 º tools are most effective at R angles of 0.4 and 0.8. An R angle of 0.2 should be avoided because it increases the likelihood of chipping.

Advantages of Chain Headway MSP & CMSP Indexable Mini-Chamfering End Mill Cutters

Our MSP and CMSP indexable mini-chamfering end mill cutters with indexable insert blades deliver significant advantages over fixed angle welded cutters. They are more cost-effective than fully adjustable cutters when the requirement is to cut standard 45º chamfers.

For extended durability and the highest precision of finish, our CMSP carbide end mill cutters offer a cost effective upgrade from standard alloy MSP mini-chamfering cutters.

| Quality and Convenience | Regrinding and loss of precision associated with welded cutters is avoided because blades (inserts) are simple to rotate or replace when worn |

| Suitable for machining small parts | Precision and stability with a small cutting diameter make the MSP and CMSP cutters ideal for manufacturing small items, including watch parts and electronic components. |

| Cutting Material Selection | Any material can be cut with the same tool simply by fitting a suitable cutting insert. |

| Interference Free Operation | The clearance angle of our 45º tool avoids tool and workpiece interference during v-grooving and spotting-drilling. |

| Improved Life | Experience improved working life and reduce costs because all four sides of the blade can be used |

| Enhanced Safety | A safer working environment comes from precision cutting that reduces burring and chipping |

MSP Mini-Chamfering End Mill With Alloy Shank

CMSP Carbide Steel Mini-Chamfering End Mill

How can Chain Headway meet your chamfering cutter requirements?

To learn more about how Chain Headway can meet your chamfering cutter requirements please contact us, or see us in our booth at EMO Hannover 2023! As a global partner to generations of CNC and machining businesses you will find our wide range of products are ready to supply any machining need.