Lightweight, aluminum changeable milling cutter with fully adjustable inserts for dynamic stability

Aluminum Adjustable Milling Cutters for Mirror-Like Finishes

High speed, precise, adjustable cutting edges and excellent stability are the key factors in achieving very high cutting precision and mirror-like finishes with Chain Headway’s HCM aluminum adjustable milling cutters.

Features of HCM Aluminum Changeable Milling Cutters

- Lightweight aluminum design for high-speed operation

- Dynamically stable

- Fully adjustable inserts

- HCM II integrated water cooling extends tool life & improves finishes

- Wide range of inserts type suitable for cutting different materials

Lightweight Aluminum Design for High-Speed Operation

The HCM adjustable milling cutter is made of lightweight aluminum alloy to enable milling at up to 12,000 rpm. Excellent flatness and mirror-like surface finishing depend on high-speed rotation, and results at high speeds are superior to low-speed cutting.

Dynamically Stable

Axial dynamic balance enables exact adjustments to ensure very high stability and minimize vibration, this is especially important when machining non-ferrous metals.

Fully Adjustable Inserts

- V-Groove design reduces vibration & increases durability

- Multiple inserts increase cutting efficiency

- Precise adjustment reduces lapping marks

- Individual dynamic balancing reduces vibration

Multiple inserts improve chip clearance during aluminum alloy machining, especially when using carbide inserts. This provides a very economical alternative to all carbide cutting tools. Chain Headway supplies a wide range of insert types for face milling of different materials.

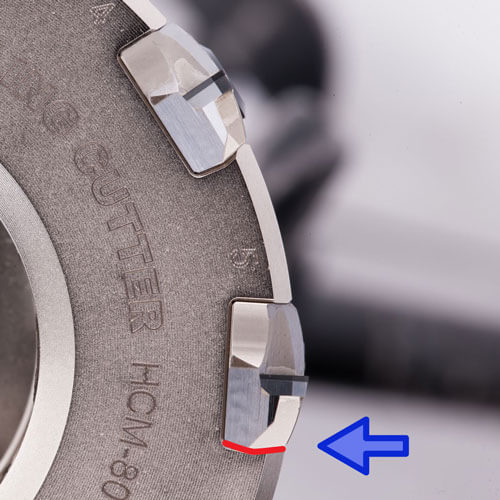

V-Groove Design Reduces Vibration & Increases Durability

Our V-Groove design ensures precise location of inserts with no gaps. This reduces vibration and increases the durability of the cutting tool and inserts.

Multiple Inserts Increase Cutting Efficiency

Our designs feature multiple cutting edges to increase cutting efficiency. The number of cutting inserts rises as tool diameter increases. This means cutting efficiency is maintained regardless of the size of the cutting tool.

Precise Adjustment Reduces Lapping Marks

Precisely adjustable inserts enable all cutting edges to be set to the same height to achieve mirror-like finishes without lapping marks. Cutting heights can also be adjusted to achieve a patterned finish if required.

Individual Dynamic Balancing Minimizes Vibration

Each insert seat has an individual dynamic balance screw enabling fine tuning of tool balance without compromise. This makes it possible to reduce vibration to an absolute minimum by careful adjustment.

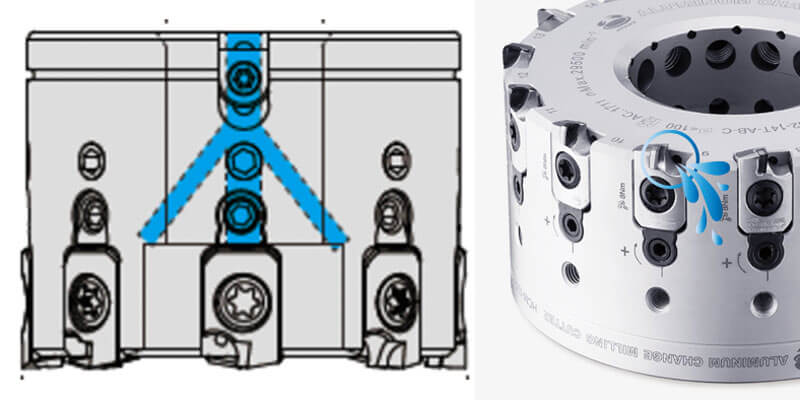

HCM II Integrated Water Cooling Extends Tool Life & Improves Finishes

The innovative HCM II aluminum changeable milling cutter features through-tool water cooling to reduce cutting temperature and assists chip removal from the cutting surface. This extends tool life and further improves surface finishes.

Wide Range of Wiper Inserts Suitable for Milling Different Materials

Chain headway manufactures standard, polycrystalline diamond and tungsten carbide inserts to enable machining of a wide range of ferrous and non-ferrous metals. Please refer to our catalog for full details.

Standard Insert

PCD Insert

R300 for mirror finishing

R500 for mirror finishing

Tungsten Carbide Inserts for P, M & K

Indexable Inserts Reduce Cost

For production lines or mass production, the Chain Headway’s HCM adjustable milling cutter reduces the cost compared to traditional disposable face milling tools. Replaceable cutting inserts are easily changed when they wear out, and a set of inserts can be installed for different materials without needing to buy an entire new tool.

Applications of HCM Aluminum Changeable Milling Cutters

- Cost Effective Tool Selection

- Ideal For Automotive Cylinder Milling

- Perfect For Mirror-Like Surface Finishing

Cost Effective Tool Selection

Using different inserts for rough cutting or finishing offers significant cost savings by reducing the number of cutting tools that need to be purchased. Simply change the insert type when working on a different ferrous or non-ferrous metal.

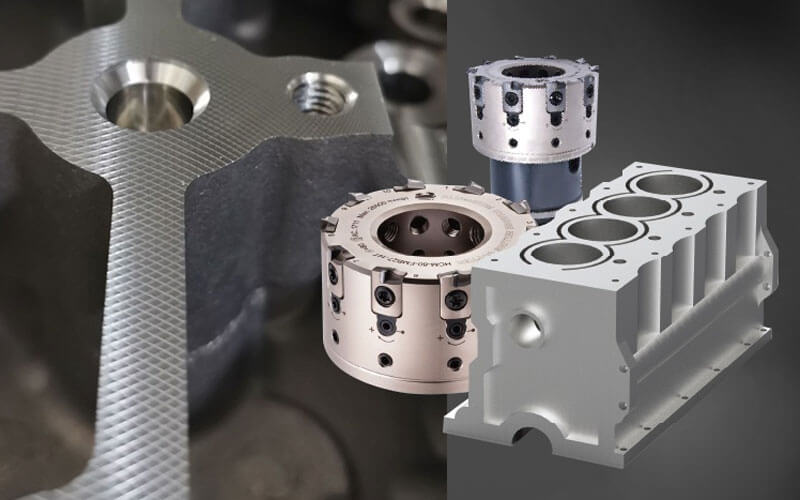

Ideal For Automotive Cylinder Milling

Extreme cutting accuracy and flat finishes are ideal for automotive cylinder milling. Individual adjustment of cutting inserts enables customized crosshatch patterned surface finishes if desired for perfect gasket seals.

Perfect for Mirror-Like Surface Finishing

The combination of light weight, high speed, dynamic stability and changeable inserts to suit different materials make Chain Headway’s adjustable milling cutters the perfect choice when you want to achieve a mirror-like surface.

Benefits of In-House Design

The core business of Chain Headway is our in-house design and manufacturing of cutting tools. Our long experience in design and supply of high quality cutting tools for different industries has made us expert in meeting customer requirements, and has driven our innovations in tool insert manufacture.

At Chain Headway, we have a deep understanding of cutting tool requirements for different machining operations. Because we manage all our design and manufacture in-house, we are able to rapidly respond to customer requests for in-depth technical advice and support. Please contact us to discuss how our HCM aluminum changeable milling cutters can meet your specific needs.