Precision. Stability. Efficiency. Our Extended Hydraulic Toolholder is the ultimate solution for deep hole machining.

In modern precision machining, the toolholder serves as a critical component connecting the machine spindle and the cutting tool. Its performance has a direct impact on both machining efficiency and quality. Among various high-performance toolholders, the extended hydraulic toolholder stands out for its unique advantages in deep-hole machining and complex cavity operations.

Technical Features of the Extended Hydraulic Toolholder

Developed from the standard hydraulic toolholder, the extended version is characterized by a longer shank, making it suitable for operations that require deeper reach. In addition to its extended length, this toolholder typically offers the following technical features:

Key Technical Features of the Extended Hydraulic Toolholder

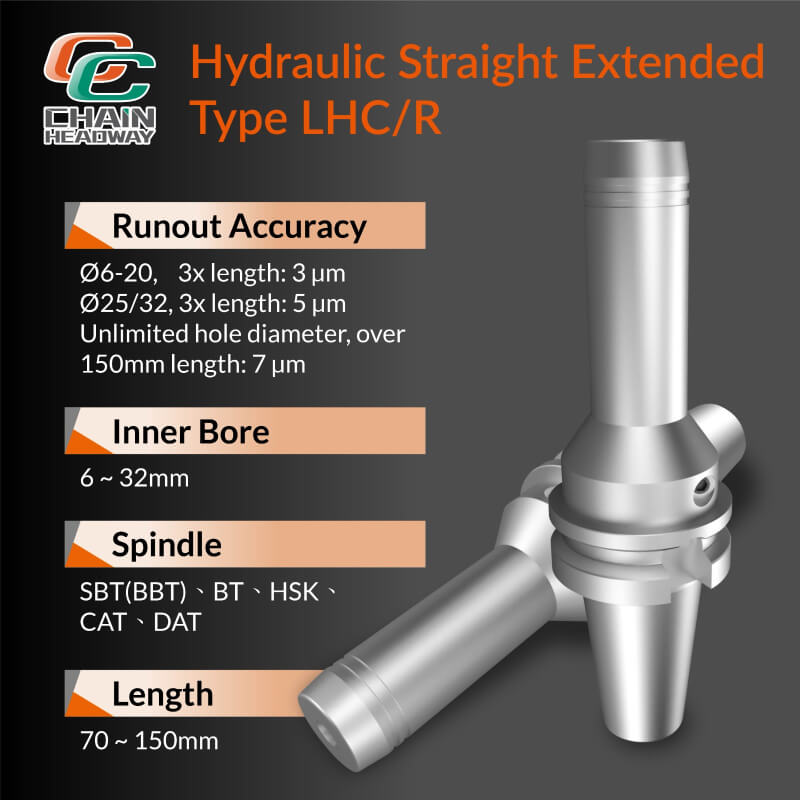

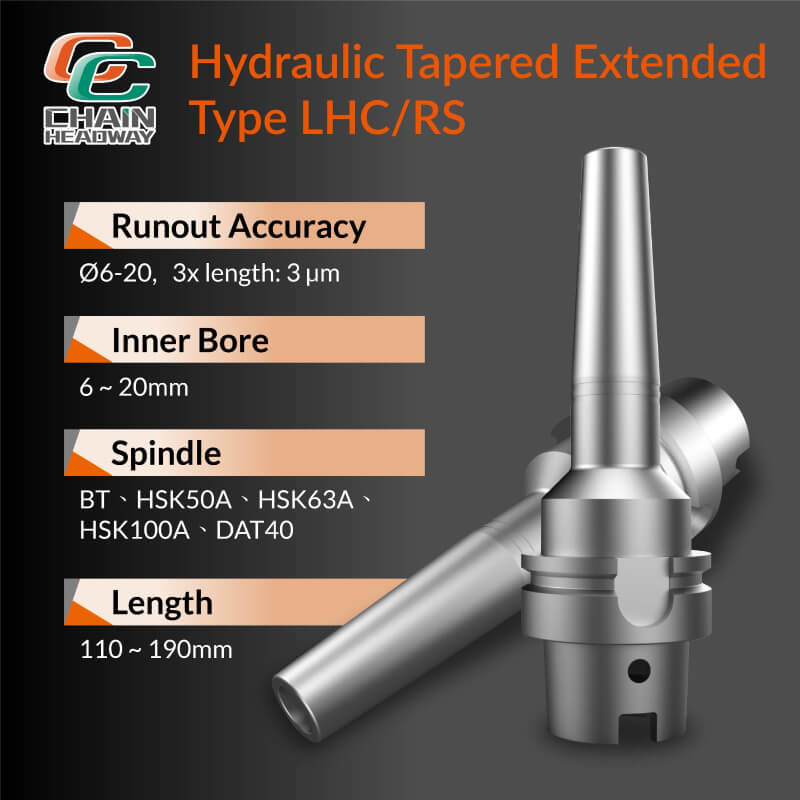

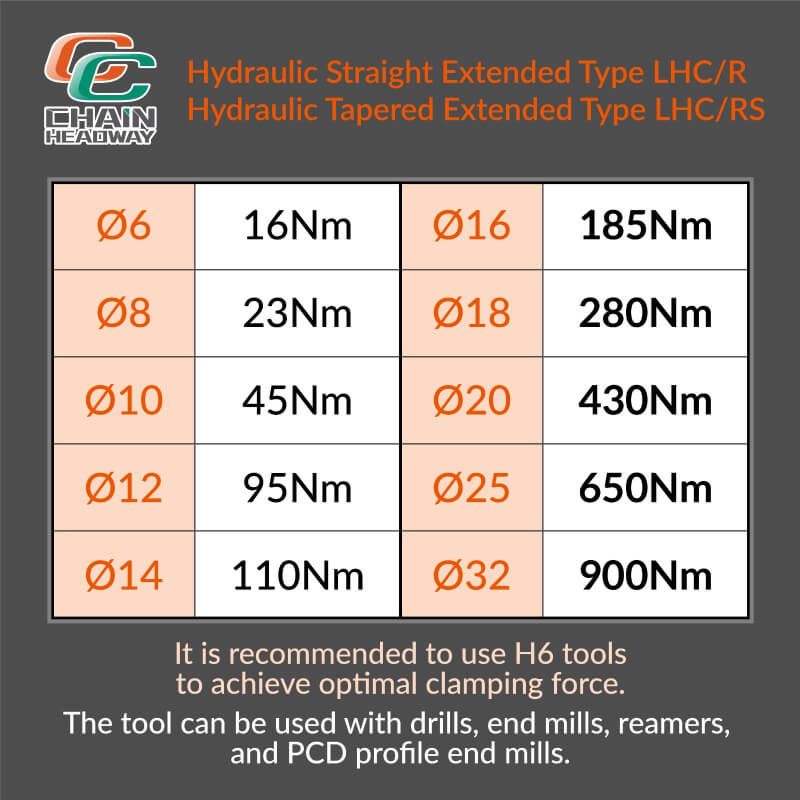

- High Precision: The extended hydraulic toolholder inherits the high-precision characteristics of standard hydraulic holders. With concentricity and repeatability typically within 0.003 mm (at 2.5D), it ensures excellent machining stability and accuracy.

- High Rigidity: To maintain rigidity in extended configurations, these toolholders are designed with optimized structures and materials. This reduces vibration and deformation during machining.

- Superior Damping Performance: The inherent damping capability of the hydraulic system effectively absorbs vibrations generated during cutting, improving both surface finish and tool life.

- Easy Tool Change: The hydraulic clamping mechanism allows for fast and convenient tool changes without the need for special tools, enhancing operational efficiency.

Applications of Extended Hydraulic Toolholders

- Deep-Hole Machining: In industries such as mold making and aerospace, deep-hole drilling is frequently required. The extended hydraulic toolholder provides the necessary reach for accessing and machining the bottom of deep holes.

- Complex Cavity Machining: For components with intricate internal features, the cutting tool must reach deeper areas. Extended hydraulic toolholders offer the access and stability needed for such tasks.

- Machining of Difficult Materials: Materials like titanium alloys and high-temperature alloys are prone to vibration during machining. The damping characteristics of extended hydraulic holders improve stability and ensure high machining quality.

Advantages of Extended Hydraulic Toolholders Over Other Toolholders

- Compared to other types of toolholders, extended hydraulic toolholders offer the following advantages:

- Versus ER Collet Holders: Extended hydraulic toolholders generally provide superior precision and rigidity compared to ER holders, along with significantly better vibration damping capabilities.

- Versus Side-Lock Holders: Extended hydraulic holders allow for easier tool changes and deliver enhanced damping performance, improving overall machining stability.

- Versus Heat-Shrink Holders: Unlike shrink-fit holders, extended hydraulic toolholders do not require any special heating equipment for tool clamping or release, making them more user-friendly and efficient to operate.

As a high-performance solution, extended hydraulic toolholders have broad application potential in the field of precision machining. With the increasing demand for higher accuracy and efficiency in manufacturing, they are set to play an increasingly vital role.

For more information and the latest updates, visit our official website or follow us on Instagram, Facebook, and LINE. To explore our full product range, please download the catalog here: Extended Hydraulic Tool Holder Series 2025.

Let’s work together to unlock cutting-edge and efficient machining solutions!