Drilling is the most common machining process, and every workshop uses drills. Companies look for fast and accurate drilling methods to keep costs down. Our tungsten carbide drills with internal coolant systems are the best option for cost-effective drilling especially for deep hole drilling in hard materials.

Cost Effective Drilling

The three most important factors in drilling operations are:

- Rapid Cycle Times

- Increasing Throughput

- High Quality Results

In today’s markets, competitive advantage comes from rapid cycle times and increasing throughput without reducing quality. Drill bit and drilling machine technology works to extend the life of drills and increase efficiency.

Time lost replacing tools and maintaining machines costs money. Profitable drilling demands rapid cycle times, high throughput and high quality results at a low cost per unit of production.

At Chain Headway we have designed tungsten carbide drill bits with internal cooling systems that are very cost effective. Our DR Tungsten Carbide drills improve drilling quality and speed and make it more profitable.

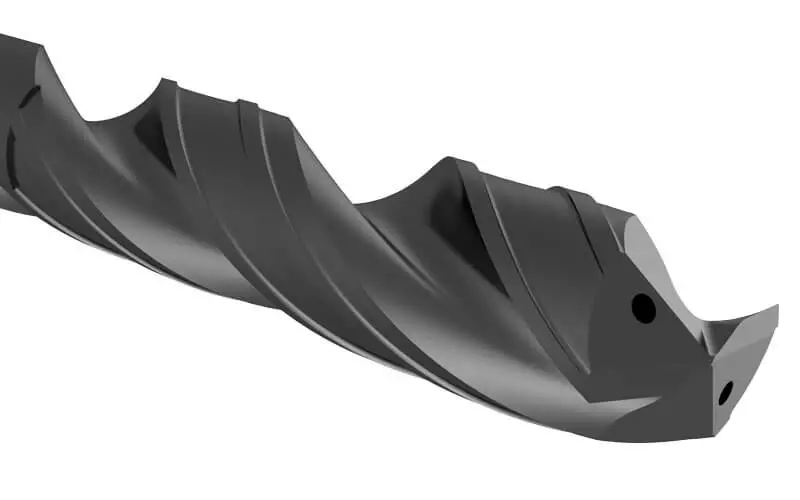

Tungsten Carbide Drills with Internal Cooling Systems

Our tungsten carbide drill designs are based on customer feedback and requirements. This made us design the best possible drill for almost any drilling operation. Customers want performance and low cost per unit of production. We used our long experience as a drill designer to make this possible.

The result is our tungsten carbide drill with a built-in cooling system. Adding an internal cooling system that clears chips from the work face extends maintenance intervals. This makes tungsten carbide drills significantly more cost effective than HSS drills.

We designed a collet chuck that can be fitted to standard drill heads that enables coolant to be pumped down through the drill bit. The coolant reaches the place it is needed most, where the drill is hottest, and it also clears chips from the working area very effectively.

Drill Technology

To see the benefits of direct cooling of the work surface at the drill head, we need to understand how different types of drill bit work. Improvements in technology have led to the development of a wide range of drill bit and coating options.

There are three features of drills that affect their performance:

- Material

- Coating

- Geometry

Material

How long a drill will last depends on how hard the drill is and how hot it gets. Standard High Speed Steel (HSS) bits are inexpensive per unit but wear out quickly. HSS bits with cobalt (HSSC) are more durable and more expensive. Tungsten carbide bits are the toughest and last the longest, but are also more expensive.

Coating

Coating a drill with a harder material makes the drill last longer and enables faster drilling and drilling of harder materials. Coatings wear away, especially if the drill becomes too hot. They are not a good alternative to a higher quality drill bit for high throughput work.

Geometry

The shape of the drill bit makes a lot of difference to how easily it can drill into different materials. When selecting drills it is very important to match the geometry of the bit to the drilling material. This is very important if holes are drilled at an angle to the work surface.

Incorrect geometry causes rapid wear, breakages and damage to the work piece. The best drill manufacturers make drills with different geometries to match customer drilling requirements.

No Spot Holes Required

The unique geometry and 140° degree drill point angle of our tungsten carbide drill bits means not spot holes are required before drilling the larger hole. Chain Headway drills can maintain true position without spot holes and therefore create large cycle time cost savings for customers.

The Perfect Drill

The perfect drill must be very precise, keep the working area cool, and remove chips rapidly. This is essential for high speed throughput and rapid cycle times. Profit increases because drill bits last longer and the quality of the finished product is higher.

Effective cooling and chip clearance have the biggest impact on drill wear and breakage. They also improve the quality of cut and enable high speed production. The perfect drill will keep the drill bit cool and clear of chips.

The Perfect Drill Bit

The perfect drill bit cuts very rapidly and accurately, is low maintenance and has a low cost per unit of throughput. It is not the cheapest drill bit, but it lasts the longest. The key success factor for business profitability and competitiveness is cost per unit manufactured.

Tungsten carbide drill bits are a logical choice because they last a long time and stay sharp. HSS drill bits are cheaper, but wear out rapidly and require frequent sharpening and changing. Every time you have to change a bit you have to stop work and lose some profit. This is the extra cost of using HSS drill bits.

Cooling Chip Clearance

Cooling is very important as too much heat damages coatings on drills and weakens drill bits. The biggest problem with cooling drills is that the hottest part is inside the hole being drilled. Conventional cooling systems cannot keep the cutting edge of the drill cool in high-speed operation.

Chips that stay in the hole at the cutting-edge cause additional wear on a drill bit. This means bits need to be changed more often. Chips can also reduce the quality of the hole being drilled. This increases wastage when finished products fail to meet quality standards.

Integrated Drill Cooling Systems

At Chain Headway we have designed a way of cooling drills more effectively by channeling coolant through the drill chuck and down the centre of the drill bit. The coolant comes out next to the cutting tip of the drill. This cools the hottest parts of the drill and clears chips by washing them up and out of the hole being drilled.

Our internally cooled bits are the best choice for high speed operations. Concentrated cooling and rapid chip clearance increases the life of the drill bit and improves production quality. When combined with tungsten carbide heat and wear-resistant drill bits, our direct cooling system offers the fastest possible throughput at the lowest cost per unit manufactured.

Cheap Drill Bits Cost More

Tungsten carbide drills are more expensive than standard steel bits. Many small businesses buy high speed steel (HSS) or high speed steel with cobalt (HSSC) drill bits because you get more drill bits at the same cost. This is a false economy.

You might need ten HSS bits to do the work of one tungsten carbide bit. If the tungsten carbide is more than ten times the price then HSS looks like good value. This is a mistake because there is a hidden additional cost for HSS bits. HSS bits wear out faster and replacing worn or broken bits stops production.

- HSS bits are cheaper but have a short life

- Silicon carbide bits last a long time but are more expensive

- HSS bits need to be changed more often than silicon carbide bits

- Changing bits stops production

- Stopping production reduces income

- Long lasting tungsten carbide bits are the lowest cost option

Tungsten carbide bits are better for maintaining throughput and rapid cycle times because they last many times longer than steel bits. Your business process becomes more profitable the longer your tungsten carbide bit lasts without requiring maintenance.

Long Life Chain Headway Tungsten Carbide Bits Are The Best Choice

Chain Headway supplies tungsten carbide bits that have a very long life. Our internal cooling system reduces wear and increases the quality of the cut. Our internally cooled drill bits are significantly cheaper than HSS drills when you add up the operational costs per unit of throughput.

Buying HSS drills on a price per unit comparison with tungsten carbide bits is a false economy. This is because when you add the loss of income caused by changing worn out HSS bits and the cost of wastage from low quality cutting the HSS bit is more expensive.

Chain Headway high quality long-life tungsten carbide bits make high speed, high throughput drilling more profitable and offer the best solution for reliable and consistent drilling results.

If you would like to find out more about tungsten carbide bits, please contact us.