A cost effective and flexible presetter that can be accessorized for any type of tooling measurement. Ideal for smaller workshops using CNC machines for precision manufacturing.

A Cost-Effective Alternative to Optical Micron Grade Tool Presetters

For CNC machining, micron grade accuracy of cutting tool measurement is essential. This can be achieved by manual measurement of tool dimensions or optical measurement. For most purposes a high quality manual micron grade tool presetter can provide you with all the precision you need at an affordable price. As a CNC tooling manufacturer, Chain Headway has designed a manual micron grade tool presetter that is very accurate and affordable.

Optical Micron Grade Tool Presetters

Mass production facilities equipped with multiple CNC machines often use optical micron grade tool presetters for tool measurement. These are large and expensive machines that use cameras and digital programming to measure CNC tooling and generate G-code compatible data for programming CNC machines.

Meeting Small Workshop Tool Presetting Needs

For small workshops and independent CNC machine operators optical micron grade tool presetters are too expensive to be affordable. As a CNC cutting tools manufacturer we have applied our experience and expertise to design a cost-effective tool presetter to meet the precision requirements of small workshops for accurate CNC machining.

Applications of the Micron Grade Tool Presetter

- Adjustable for Various Tool Types

- Deflection Measurement

- Measuring Length of Cutting Tools

- Measuring Close-Tooth Cutters, Boring Cutters & Other Tools

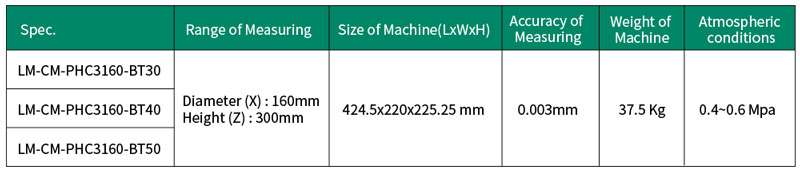

The modular design of the Chain Headway LM-CM-PHC3160 Micron Grade Tool Presetter enables fitting different measurement tools to get any measurement you require. The pneumatic vacuum fit of the tool holder provides a secure and reliable grip that improves the accuracy of repeated positioning of the tool for measurements.

Adjustable for Various Tool Types

We manufacture our micron grade tool presetter in three different models to suit spindle sizes of BT30, 40 & 50, these feature extremely high precision of 0.003mm for tools upto 300mm in length. To ensure accurate results it is necessary to use a tool presetter that matches the spindle size of your cutting tools.

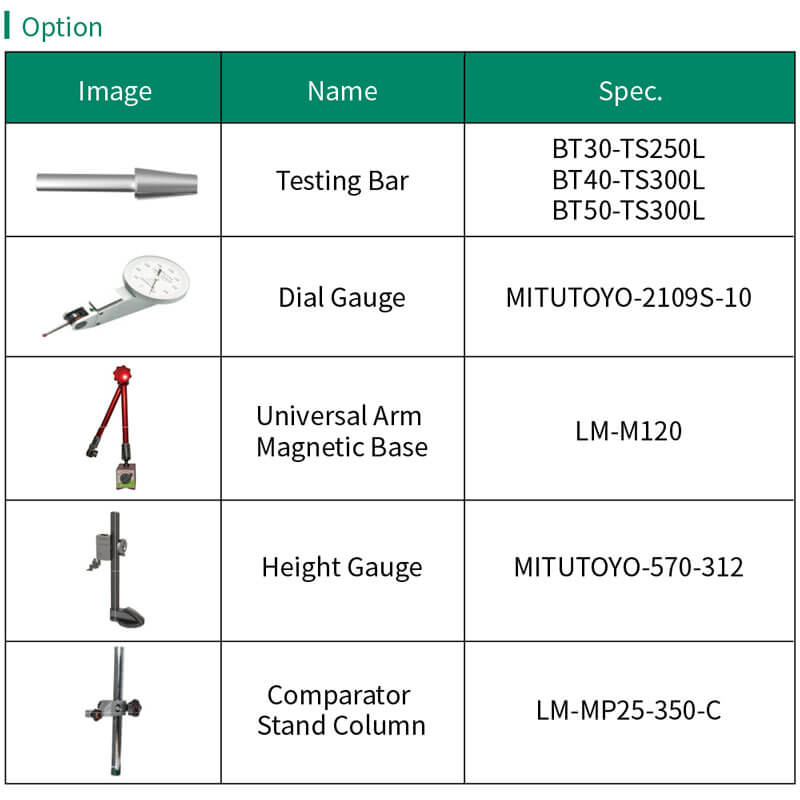

The Chain Headway Micron Grade Tool Presetter can be accessorized and adjusted to supply almost any tool measurement you need in the most cost-effective way. We supply a variety of optional accessories for measuring different tool dimensions – you only need to buy the measurement tools you need for your specific CNC machining requirements.

Accessories & Optional Measuring Tools

The Chain Headway Micron Tool Presetter comes equipped with a spindle cleaner bar as standard. We offer a range of optional tools and accessories to enable tool length, deflection and profile measurement for standard and specialised CNC cutting tools.

Deflection Measurement

Install the optional dial gauge on the universal arm magnetic base to accurately detect the deflection of the cutting tool.

Measuring Length of Cutting Tools

With the height gauge fitted, the length of the cutting tool can be very accurately measured.

Measuring Close-Tooth Cutters, Boring Cutters & Other Tools

Settings can be easily adjusted to measure a very wide range of tools including close-tooth cutters and boring cutters.

Benefits of In-House Design

The core business of Chain Headway is the in-house design and manufacturing of CNC cutting tools. As a CNC cutting tools manufacturer our experience of designing and supplying high quality CNC cutting tools makes us experts in tool measurement and calibration.

We have used our experience to design a cost-effective micron grade tool presetter that can be customized to meet any requirement you may have without the need to invest in complex, expensive micron tool presetters using optical systems.

At Chain Headway we have a deep understanding of the range and specifications of tools for different machining requirements. Because we manage all our calibration and measurement tools in-house, we are able to rapidly respond to customer requests for in-depth technical advice and support.