Innovative Cutting Tools for Energy Sector Applications

Reliable and Versatile Cutting Solutions for any Task

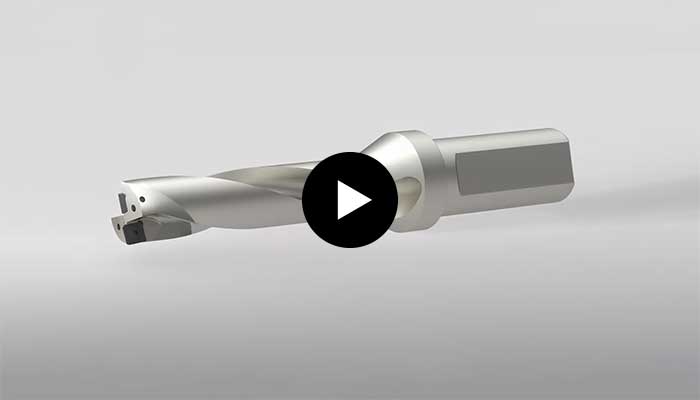

Chain Headway produces a wide range of high reliability energy sector cutting tools, which address the essential requirements for milling, drilling, turning and threading.

Our focus on innovation and enhanced cutting and milling technology enables us to supply cutting and milling tools that can be customised to meet any of the varied demands found in energy industry applications.