In precision machining, the finishing cut defines the final quality. For industries like automotive and mold-making, achieving mirror-like surfaces without compromising tool life is a constant challenge. At Chain Headway, our fine-adjustment face milling cutter series is the result of years of engineering experience, offering micron-level control for consistently high-quality results.

Ultra-Precise Mirror Finishing with Micron-Level Adjustability

Chain Headway’s face milling tools feature a fine-adjustable insert seat and modular cutter head, allowing edge height control within ±1 micron. This level of accuracy achieves mirror-like surface finishes with Ra < 0.5µm across a wide range of applications. Available in diameters from 50 mm to 400 mm, this solution fits most precision CNC finishing needs.

Precision Face Milling Cutter with Micron-Level Control

- Adjustable insert seat design enables cutting edge height control within ±1µm.

- Achieves ultra-fine surface finishes as low as Ra 0.456µm with alloy steel materials.

- Ideal for mirror surface finish applications across a wide range of metals.

High-Speed Compatible and Low Vibration Design

- Supports spindle speeds up to 33,000 rpm.

- Low cutting resistance geometry (16° axial rake angle) for smoother machining.

- Patented insert seat design ensures stability at high RPMs.

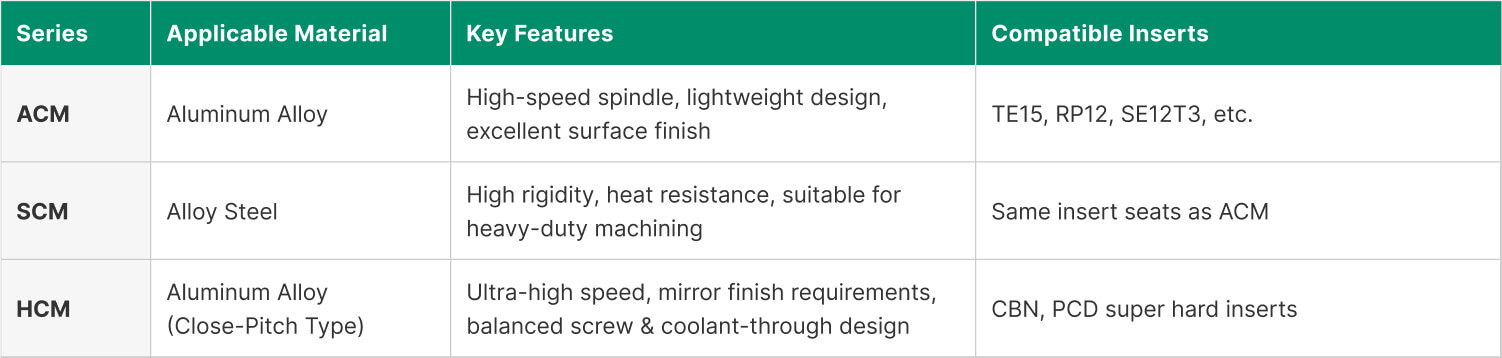

Modular Cutter Heads for Maximum Flexibility

- Modular cutter heads (ACM / SCM / HCM Series) flexibly support machining of steel, aluminum alloys, and cast iron.

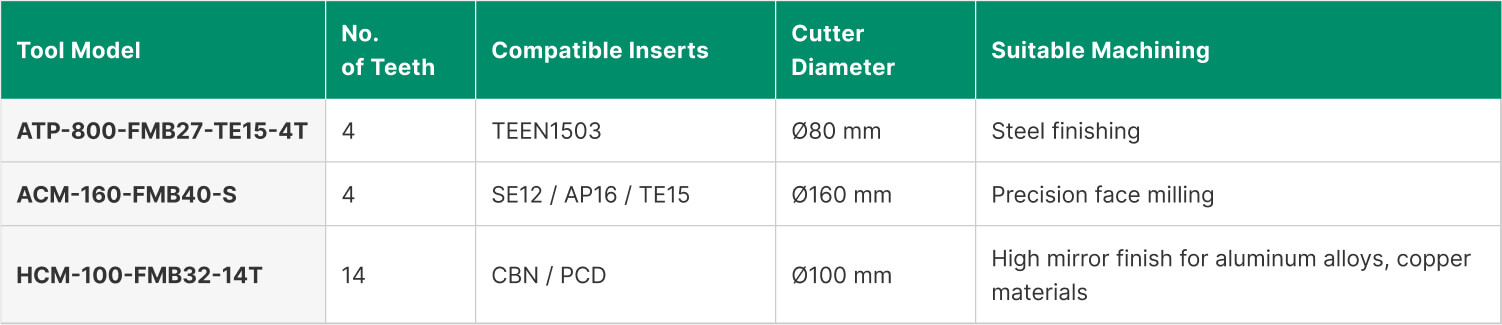

TEEN1503 Inserts for Precision Finishing

- Material Options: Cermet, coated ceramic, and ultra-fine grain carbide

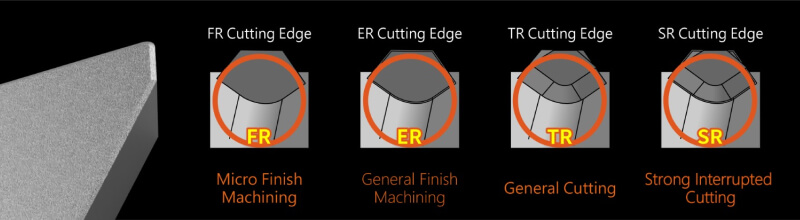

- Edge Types: Available in FR / ER / TR / SR chipbreaker geometries

- Applicable Materials: Suitable for alloy steel, stainless steel, and cast iron

- Recommended Cutting Parameters:

• Cutting Speed (Vc): 100–220 m/min

• Feed per Tooth (fz): 0.1–0.3 mm/rev

• Axial Depth of Cut (Ap): 0.1–1.0 mm

Versatile Cutters & Insert Combinations to Meet Various Machining Needs

Frequently Asked Questions

- Q1: What is a fine adjustment face milling cutter used for?

A: It is designed for high-precision CNC finishing where a mirror-like Ra surface is required on materials like steel, cast iron, and aluminum. - Q2: What insert types are suitable for mirror surface milling?

A: CBN and PCD inserts are ideal for ultra-high-speed, low Ra mirror finishing on aluminum and copper alloys. - Q3: Are these tools compatible with high-speed spindles?

A: Yes, Chain Headway cutter heads support speeds up to 33,000 rpm while maintaining stability and accuracy.

Ready to Achieve Mirror-Perfect Finishing Without Trial and Error?

Chain Headway’s fine-adjustment face milling cutter series combines precision engineering with real-world machining expertise. With ±1µm insert control and modular cutter head options, you can achieve consistent Ra < 0.5µm finishes from the very first cut. Whether your goal is high-efficiency scheduling, flexible tooling for various materials, or mirror-quality surface finishing, our team provides tailored tool recommendations and expert technical support.

For more information and the latest updates, visit our official website or follow us on Instagram, Facebook, and LINE. To explore our full product range, please download the catalog here: Micro-Adjustment Finish Face Mill Series

- 📞 Contact Us: +886-4-26268383

- 🌐 Website: www.chainheadway.com

- 📧 Email: [email protected]

- 📲 Follow Us for Updates: Instagram / Facebook / LINE – Search for “Chain Headway”