High productivity milling inserts for efficient material removal

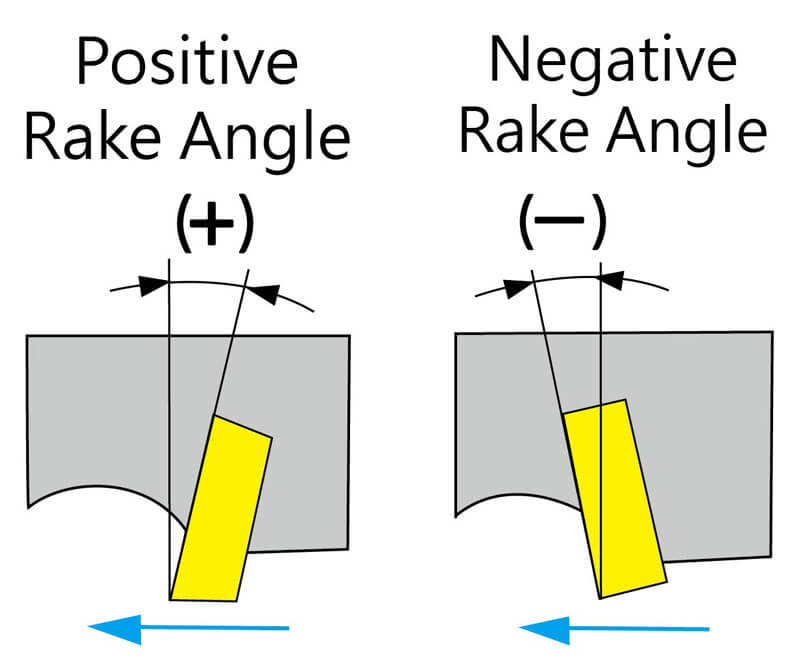

Negative vs Positive Rake Angle

If the angle between the cutting edge and the machined surface is greater than 90° this is a positive rake angle, a negative rake angle occurs when the angle is less than 90°. Negative rake angles put less stress on the cutting edge and are often better for rapid material removal than positive rake angles. Negative rake angle is preferred for machining hard and brittle materials including stainless steel and titanium.

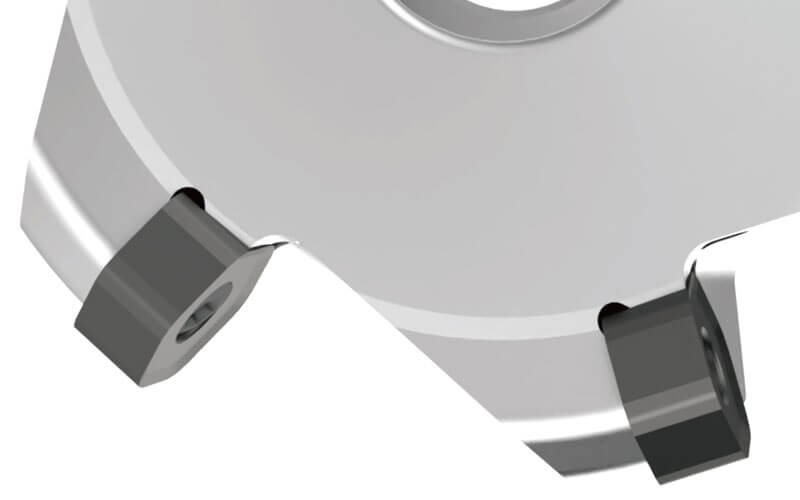

Negative Rake Angle Inserts

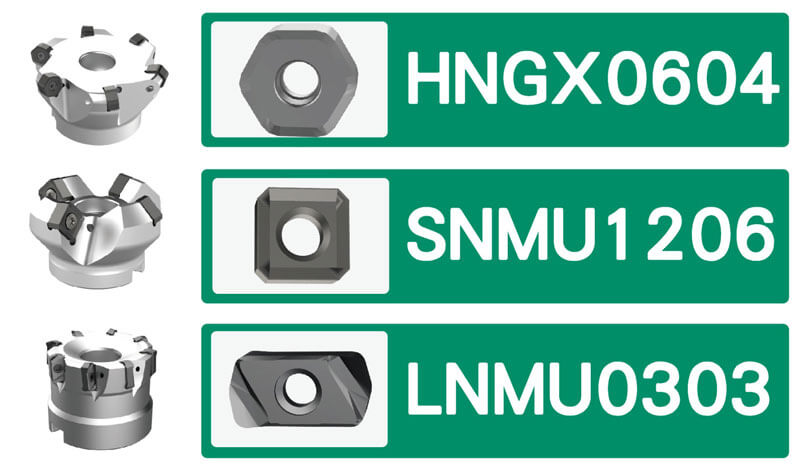

Our milling cutters come in three ranges designed for three types of interchangeable negative rake angle inserts. Our negative rake angle inserts enable cutting and milling of hard materials to the highest standards. Cutter inserts are designed to be rotated when worn to use fresh cutting edges for significantly extended life.

Negative Rake Angle Milling Cutters

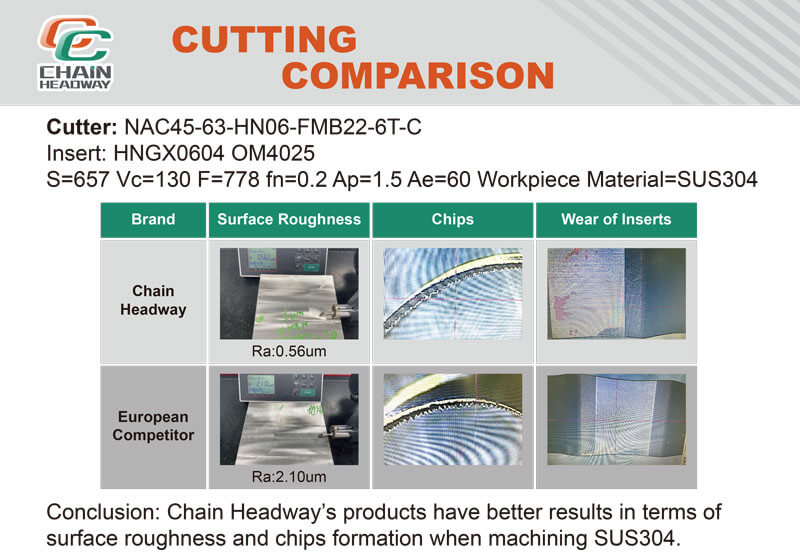

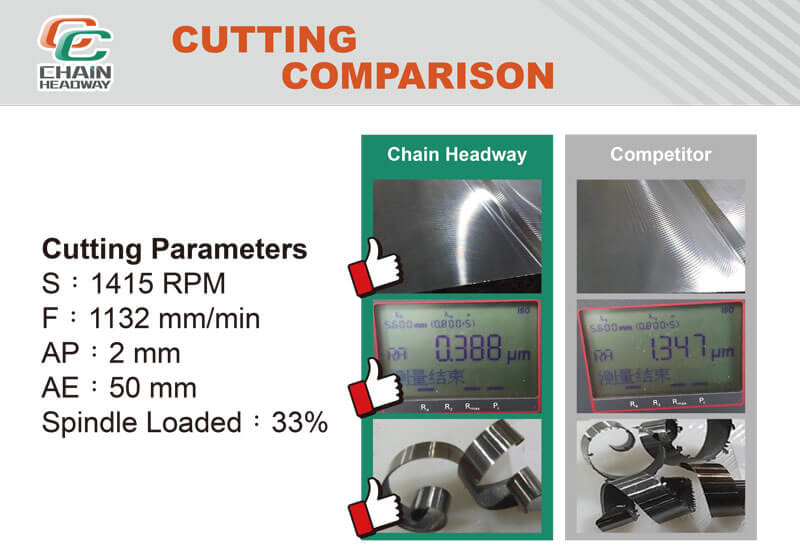

Chain Headway manufactures negative rake angle shank, screw-on, and shell milling cutters to meet any requirement you may have. Comparative tests demonstrate that Chain Headway negative rake angle milling cutters can be used for precision surface finishes, and offer the highest levels of performance available on the market today.

- Negative Angle Shell Milling Cutters

- High Feed End Mill Cutters

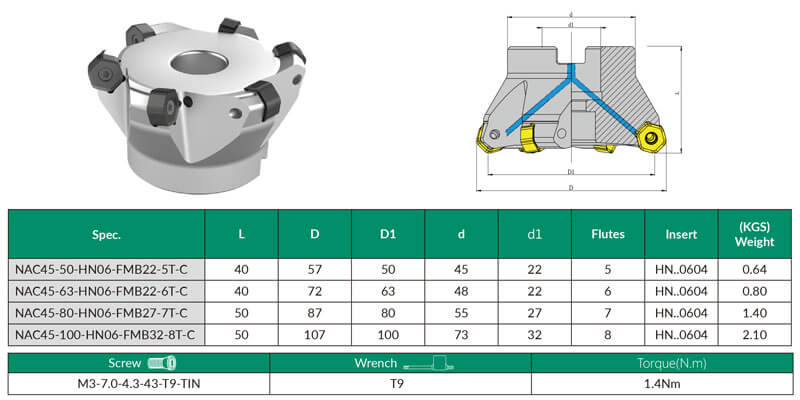

Negative Angle Shell Milling Cutters

Our NAC 45° Negative Shell Milling Cutters are available with two different insert types, providing either 12 cutting edges (HN..0604) or 8 cutting edges(SN..1206).

NAC 45° Negative Shell Milling Cutter with 12 cutting edges (HN..0604)

This shell milling cutter is ideal for semi-finish machining and rapid removal of material while maintaining a high-quality surface finish.

- Negative Angle Insert With 12 Cutting Edges

- Internal Coolant Supply

- Differential Tooth Pitch Reduces Vibration

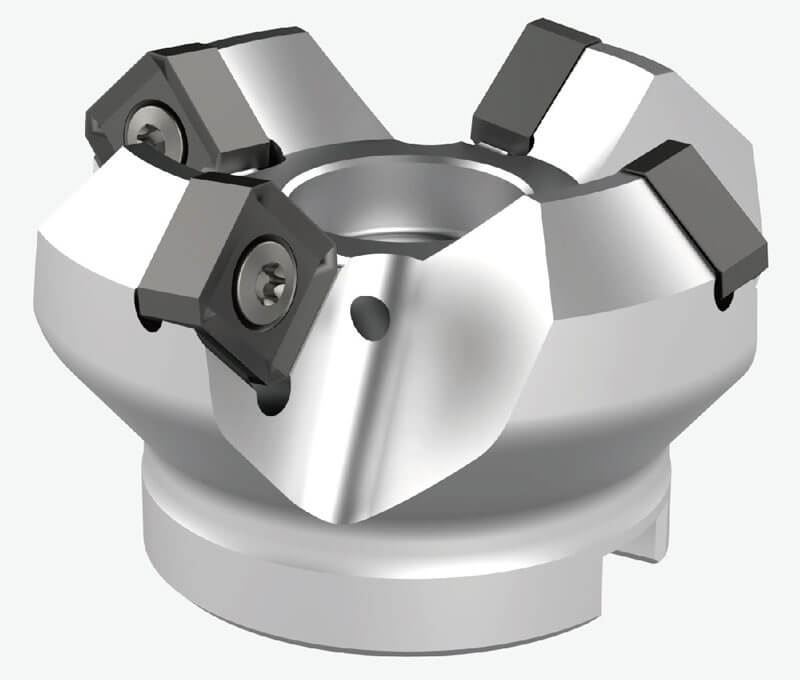

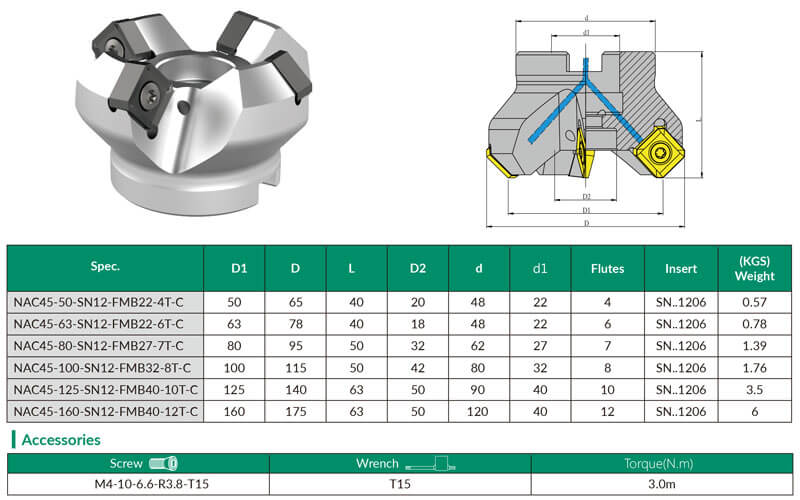

NAC 45° Negative Shell Milling Cutter With 8 Cutting Edges (SN..1206)

The NAC 45° milling cutter features between 4 and 12 flutes depending on size, and is designed to accept our negative rake angle insert with 8 cutting edges. This design can remove bulk material rapidly and with more depth of cut than the 12 cutting edge insert, making it suitable for rough machining, but with an improved surface finish compared to positive rake angle cutters.

- More Depth of Cut

- Negative Angle Inserts Provide 8 Cutting Edges

- Internal Coolant Supply

High Feed End Mill Cutters

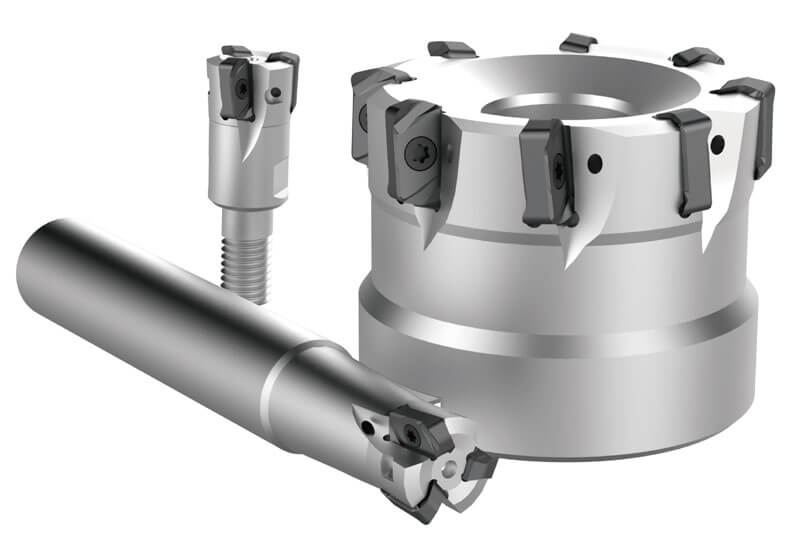

The NHF series of High Feed End Mill Cutters offer high productivity and machining efficiency in three different configurations, and have design features that make them ideal for high feed operations.

- Inserts With 4 Cutting Edges for High Machining Efficiency

- Available in Shank, Screw-on and Shell Types

- Maximum Feed Rate 1.2mm/z

Inserts With 4 Cutting Edges

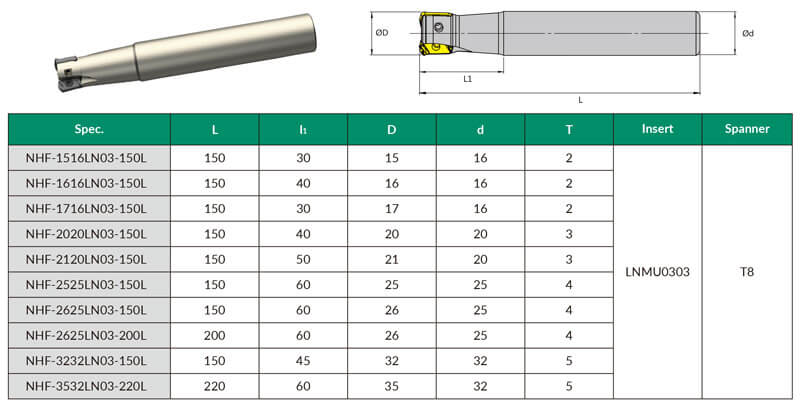

Shank High Feed End Mill Cutters

Chain Headway shank mounting high feed negative rake end mill cutters are available with between 2 and 5 flutes depending on size. Our shank mounted end mill cutters accept our 4 cutting edge insert for machining hard alloys and cast iron.

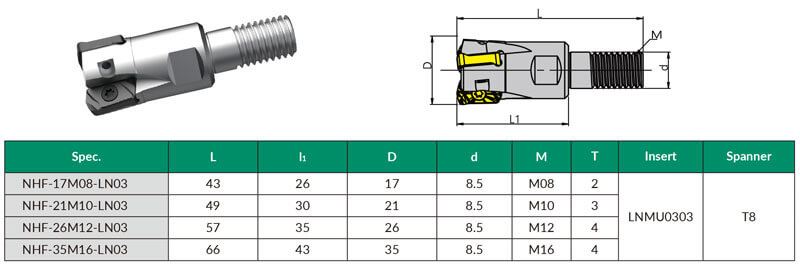

Screw-On End Mills

Our screw-on negative rake end mill cutters are configured with 2, 3 or 4 flutes. These are fitted with our 4 cutting edge insert to machine alloyed steel or cast iron, offering extended life and high performance cutting.

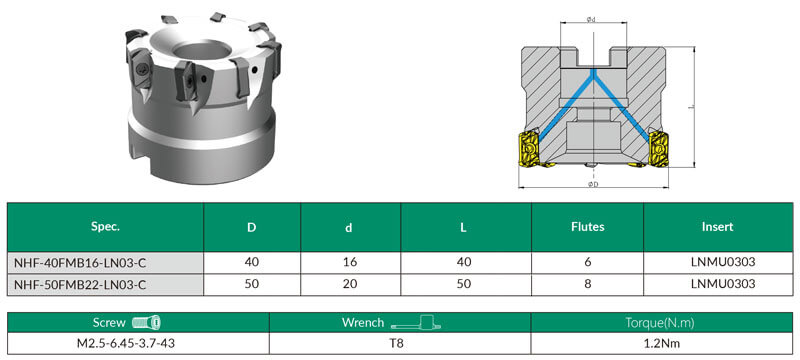

Shell-Type End Mill Cutters

Chain Headway shell-type high feed negative rake end mill cutters come in 6 and 8 flute configurations, also designed to be fitted with our 4 cutting edge inserts for precision end milling of hard alloys.

Comparative Tests Demonstrate Excellence of Chain Headway Negative Rake Inserts

Key Features of Chain Headway Negative Rake Milling Cutters

- Mounting Types: Shank, Shell, Screw-On

- Number of Flutes: between 2 and 12 depending on configuration(刃數)

- Rotatable Cutting Inserts: from 4 to 12 cutting edges depending on mounting type

- Different inserts available depending on material being cut

- Better finishes and performance than competing brands

- Long life and extended wear performance with rotatable inserts

Benefits of In-House Design

The core business of Chain Headway is the in-house design and manufacturing of CNC cutting tools. Our long experience of designing and supplying high quality CNC cutting tools for customers from different industries has made us experts in matching tools to customer requirements and production practices, and has driven our expertise in tool insert manufacture.

At Chain Headway we have a deep understanding of cutting tool requirements for different machining operations. Because we manage all our design and manufacture in-house, we are able to rapidly respond to customer requests for in-depth technical advice and support. Please contact us to discuss how our negative rake angle cutters can meet your specific needs.