In today’s manufacturing industry, choosing the right tools is crucial for improving production efficiency and reducing costs. Especially in the field of chamfering, traditional integral welded HSS (high-speed steel) chamfering cutters often face challenges such as short tool life, high costs, and low efficiency. To address these issues, Chain Headway’s MDC Multi-Axis Chamfering Cutter brings a whole new experience to machining.

Challenges of Traditional Integral Welded HSS Chamfering Cutters

- Short Tool Life: Integral HSS tools wear easily during machining, leading to frequent replacements and increased machining costs.

- Resource Waste: When the tool wears out, the entire tool needs to be replaced, resulting in unnecessary resource wastage.

- Low Efficiency: In multi-hole machining, traditional chamfering cutters have low efficiency, leading to higher labor costs.

Innovative Features of MDC Multi-Axis Chamfering Cutter

- Replaceable Insert Design The MDC Multi-Axis Chamfering Cutter features a replaceable tungsten carbide insert design that effectively utilizes three cutting edges. When the insert wears, simply replace it, significantly reducing costs. The operation is simple and similar to traditional chamfering cutters, with a low usage threshold. In addition, the insert features a special coating that aids in chip removal, and the ultra-fine particle substrate offers both toughness and wear resistance, ensuring stable and durable machining.

- Rear Support Tungsten Carbide Guide Block The cutter is equipped with a rear support tungsten carbide guide block, which effectively protects the cutter body and prevents damage due to improper use. The guide block reduces impact by increasing the contact area, making the cutter more stable during machining and resulting in a smoother surface finish. Moreover, the tungsten carbide guide block is replaceable, adhering to environmental protection concepts and reducing maintenance costs.

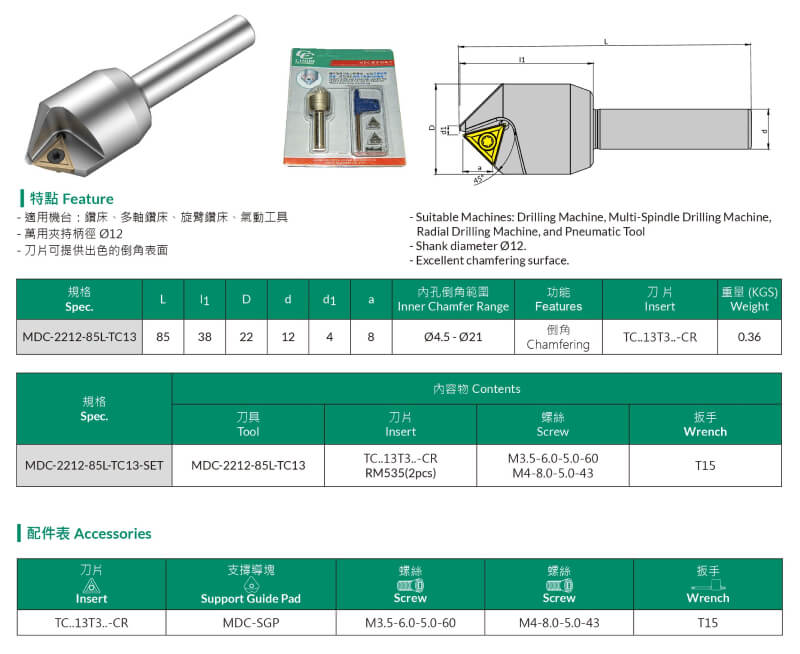

- Wide Chamfering Range The inner diameter chamfering range spans from Ø4.5mm to Ø21mm, paired with a universal shank diameter of Ø12mm, accommodating various machining needs.

- Multi-Axis Machine Synchronization MDC chamfering cutters can be used for synchronized machining on multi-axis machines, greatly improving multi-hole machining efficiency and saving labor costs.

- Enhanced Durability The tool life of MDC chamfering cutters is significantly extended, reducing downtime and improving overall productivity.

- Convenient Insert Replacement Design The screws for insert replacement do not require tool length recalibration, making the operation simple and time-saving, allowing for quick transitions into work mode.

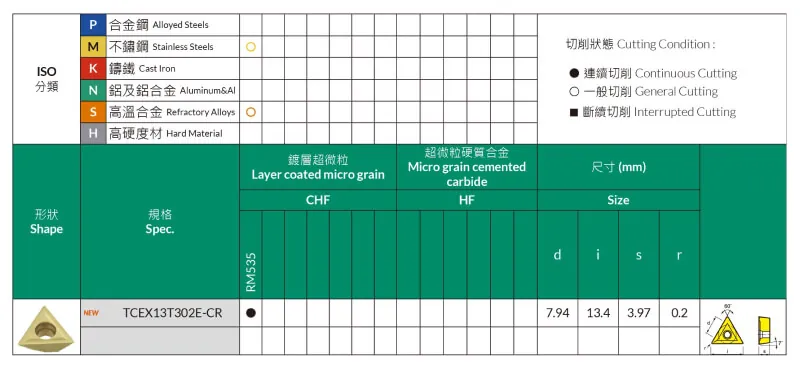

MDC Multi-Axis Chamfering Inserts

MDC Multi-Axis Chamfering Cutters utilize a replaceable insert design, offering three cutting edges. When the insert wears, it can be directly replaced without grinding, eliminating the need to replace the entire tool. This significantly reduces costs and resource waste. The special coating design provides a finer chamfering surface and aids in chip removal. The ultra-fine particle substrate offers both toughness and wear resistance, ensuring long-lasting performance.

MDC Multi-Axis Chamfering Tools

The universal shank diameter of Ø12mm ensures high compatibility. The inner diameter chamfering range spans from Ø4.5mm to Ø21mm, meeting diverse chamfering requirements. Each set includes one tool, two inserts, one tungsten carbide guide block, one wrench, and two screws for easy replacement.

Advantages of MDC Multi-Axis Chamfering Cutter

- Applicable to Various Machines: Suitable for drill presses, multi-axis drill presses, and radial drill presses, expanding the range of use.

- Economic Benefits: Effectively reduces overall tool costs, increases machining efficiency, and enhances value, making the return on investment more attractive.

- Ease of Use: Simple operation, easy to learn.

- High Durability: Extends tool life, reduces repair frequency, ensuring stability and continuity in the production process.

- Wide Application: Can be used for machining a variety of materials and hole sizes, meeting different requirements.

Recommended Parameters for MDC Multi-Axis Chamfering Cutter

Chain Headway’s MDC Multi-Axis Chamfering Cutter is the best choice for improving machining efficiency and reducing costs. Its replaceable insert design, rear support tungsten carbide guide block, and multi-axis machining advantages make the process smoother. If you want to improve overall machining quality, try the MDC Multi-Axis Chamfering Cutter for a whole new machining experience!

For more information and the latest updates, visit our official website or follow us on Instagram, Facebook, and LINE. To explore our full product range, please download the catalog here: Chamfering Cutter Series.

Let’s work together to unlock cutting-edge and efficient machining solutions!